Product Comparisons

-

Posted: May 30, 2022Read more »

The food processing industry has valued silverlined gloves for many years. While Nitrile gloves have often replaced them, silverlined gloves are still preferred in many circumstances. There are a few points that make silverlined more suitable for various tasks.

Let’s start with the term silverlined. This is an Australian term, which refers to the smooth ‘grey’ glove interior. This smooth texture is designed to make donning more efficient. The exterior of the glove (typically blue in the food industry) has a raised surface texture. Some common textures are honeycomb, fish-scale, pebble, sand patch or diamond. These are all excellent forms of grip to ensure ease of use... Sand patch is typically used in wet environments, while fish scale and diamond are more suitable for a dry environment, although these are interchangeable. Silverlined gloves are often referred to as ‘washing-up gloves’ as they are used in a domestic environment. They are the ideal heavy weight disposable

-

Posted: May 17, 2022Read more »

Long gloves or long cuffs have become a valued part of the food industry, they help to keep sleeves tucked in, extended reach, along with cleaner more protected hands. A standard long cuff glove typically reaches a further inch up the wrist. Extra-long gloves however, extend well beyond this to the elbow or further. The additional length has many beneficial purposes for the food industry. The extra reach means your team members can use them for tasks such as cleaning equipment. Allowing protection from chemical splashes, which then also protects not only direct skin contact but also uniforms and clothes.

The only alternate for a long cuff is a sleeve cover. While sleeve covers are excellent for everyday use in a food factory, specialised tasks require extra protection which is why long gloves are the best suited product. The main advantage is no gaps at the wrist, allowing complete splashproof protection for the entire arm. The nitrile chemical-resistant

-

Posted: May 02, 2022Read more »

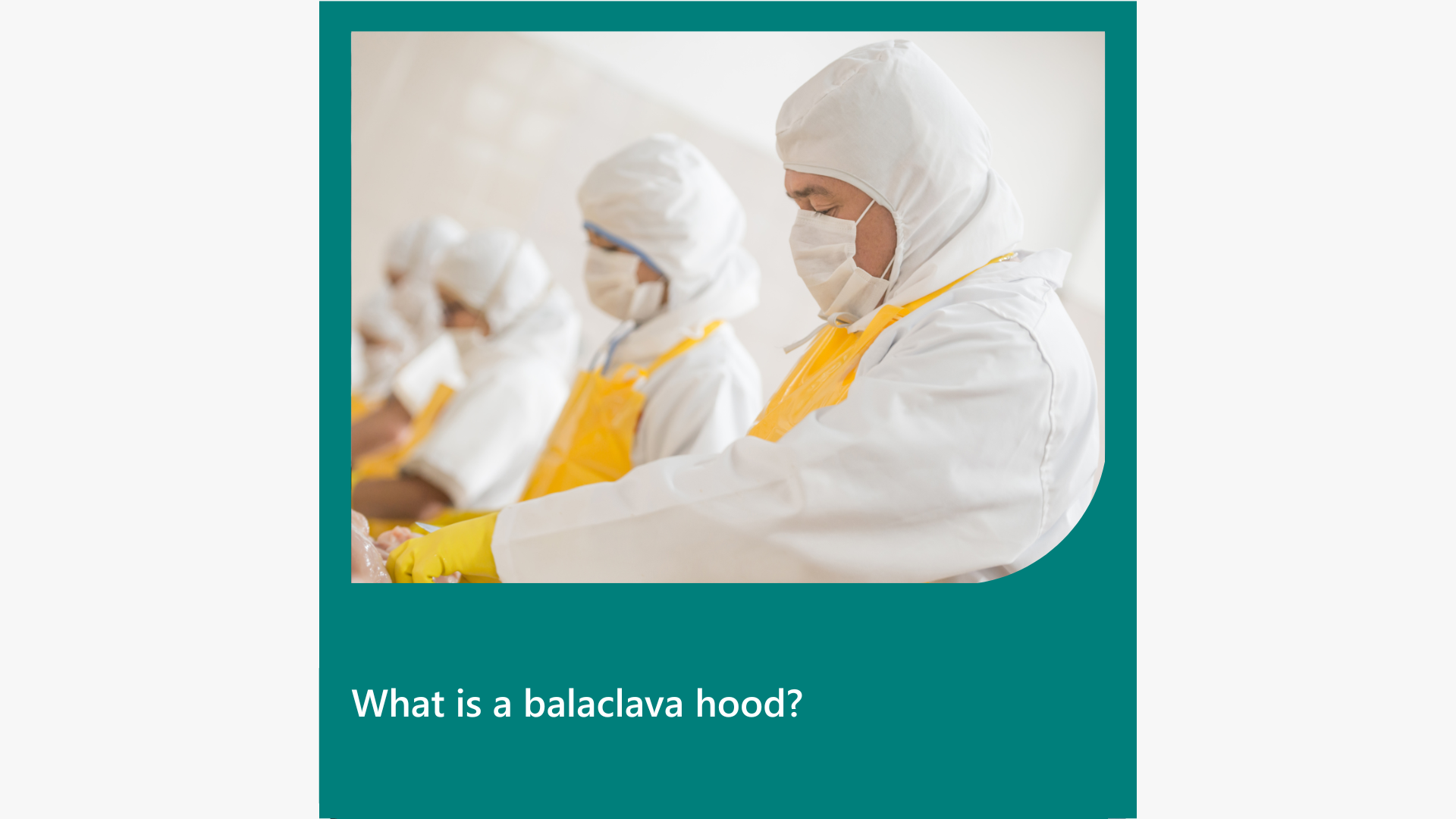

What is a Balaclava hood?

A balaclava in the food industry is the superior way to control hair contamination. Containing hair is an ongoing concern and finding a solution that works for you and your team is critical.

A balaclava is essentially a hood that fits over the head leaving an opening for the mouth, eyes and nose. There are a few varieties of balaclavas, this includes colour, size, thickness, with and without a mask, shape and finish.

The most popular being the elastic edged finish - this means the balaclava sits closely around the face and stray hairs are neatly contained.

Another advantage is the all-in-one containment. A balaclava can often substitute for both a hairnet as well as a beard net. This helps reduce costs, even though a balaclava should be replaced between shifts like an ordinary hairnet, limiting the volume required therefore creates cost efficiencies for the business.

Another consideration is comfort; finding the right balance

-

Posted: November 15, 2021Read more »

Buckets and pails are very familiar products, but they are often confused with one and another. However, there is a difference, and that main difference is the purpose.

Bucket is the more familiar term. It is a cylindrical upright open container with a handle. The primary purpose of a bucket is to transport liquids and that is why they are popular in the food industry. In addition to carrying liquids such as water and milk they are also used to carry bulk dry ingredients such as flour, sugar and spices. They can also be used for cleaning and carrying chemicals. They are designed to be a quick efficient way or transporting liquids or solids in reasonable sized quantities. Some buckets may come with lids, this additional feature is favourable to ensure the safety of your produce short term.

A pail, although having the same cylindrical appearance, is designed to be used for storage. One of the big differences is a pail usually has an air-tight or a tamper-proof

-

Posted: October 01, 2021Read more »

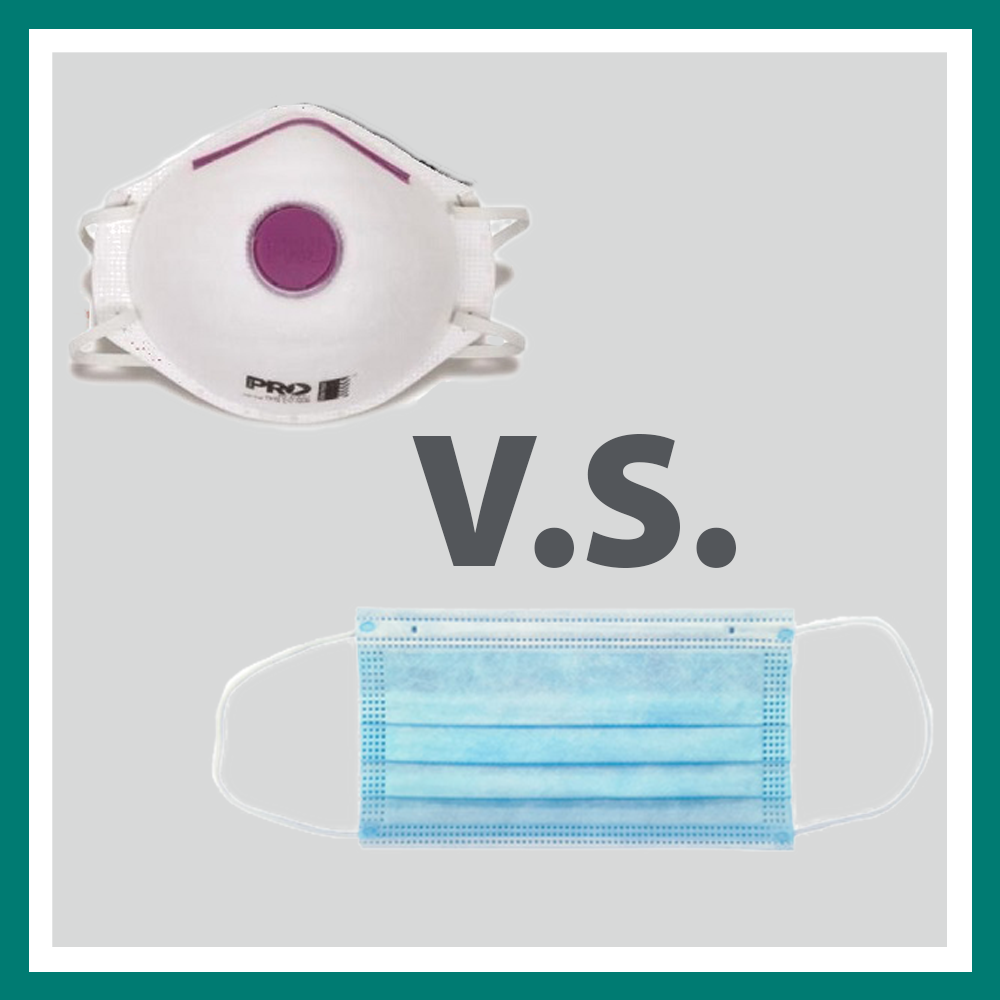

In these unprecedented times masks have become very familiar to us, but what is the difference between a mask and a respirator in their application in food manufacturing?

In our industry, masks are generally worn to protect food from the wearers respiratory emissions and a respirator is generally worn to reduce the wearers exposure to harmful particles that may be present in the air.

In many environments within the food processing industry, air quality is affected by the tasks performed, for instance, anything involving fine powders, chemicals, or dust. Our lungs are able to withstand a small amount of exposure and naturally filter out harmful particles, however being repeatedly or regularly exposed can create a build-up with potential long-term damage. Confined spaces also pose a risk as fumes and or powders are unable to disperse. So, protecting our respiratory system is important, and ensuring we aren’t spreading germs is also critical, particularly while working with

-

Posted: May 28, 2021Read more »

Dispensers in Food Production Facilities

Soap dispensers, paper towel dispensers, PPE dispensers: what makes a great design?

Efficiency is critical in production areas. Time, energy and effort are all limited, and need to be used carefully to ensure the maximum productivity.

Likewise, production consumables are just as essential in food manufacturing, for a range of purposes. The large volumes of these required demands efficient systems to allow for easy access and control so time isn’t lost and waste is controlled.

Over time, the ergonomics and basic functionality of dispensers have evolved making them more valuable and necessary in food processing than ever.

What is important in a dispenser?

A large amount of design goes into a highly functioning dispenser. Some of the basic considerations are hygiene control, reduced contact, limited waste and

-

Posted: May 03, 2021Read more »

Many types of gloves are available for Food manufacturing plants, including nitrile, vinyl and silverlined. A quality product that does not pose contamination risks to food production is paramount. Nitrile first became available in the 1990s and has become the most popular glove type within the food processing industry since then. There are many advantages to nitrile, and the varying thickness and options make it one of the most popular glove materials in the food processing industry.

Polyvinyl Chloride (PVC), or Vinyl gloves, as they are commonly referred to, are a relatively cheap option; they are a form of synthetic rubber and are stiff and less breathable than other materials. Their main benefit is their cost, usually considered reasonably cheap. Typically preferred when multiple ingredients are in use, gloves must be changed frequently.

However, due to their stiff nature, they often will tear when donning the glove, resulting in many employees choosing to wear two gloves

-

Posted: April 19, 2021Read more »

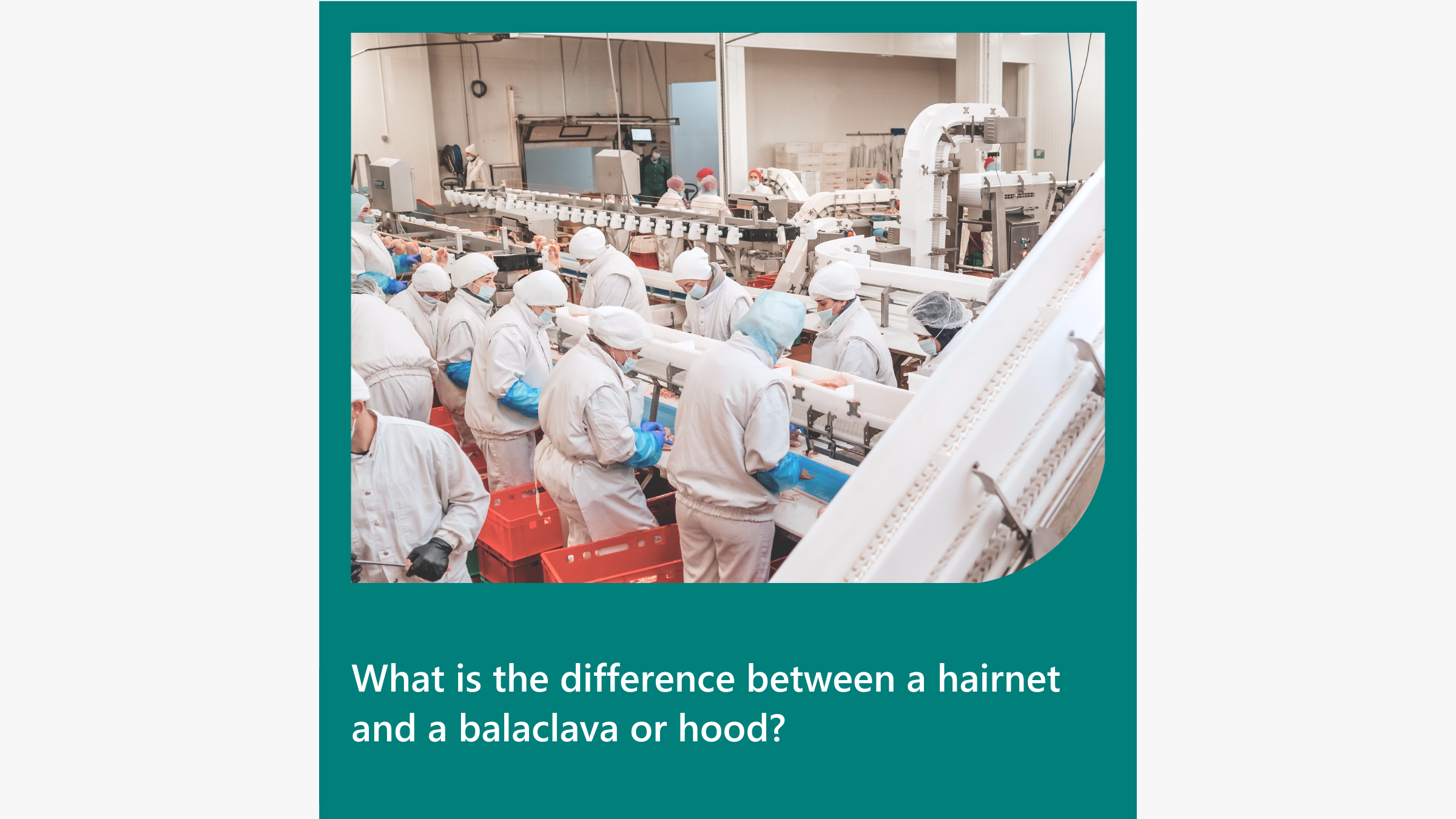

Reliable and competent hair control is essential for all food processing companies. Requirements can vary extensively by site, and each company must decide what is suitable for their needs, and what is required to meet their audit requirements. There are many kinds of hair control available and deciding on the right product must be chosen by a balance of quality, comfort, and suitability.

Falling under the hygiene wear sector, hair control products are typically disposable. A quality product features high strength breathable material, and tight enduring elastic while completely enclosing the hair. Hair control products are not effective unless they are worn unceasingly in the production area.

What variety of hair control is there?

The most common type is typically referred to as a hairnet. These are typically a crimped piece of non-woven polypropylene with an elastic edge. They typically cover the top of the head but will often fail to provide sufficient cover

-

Posted: March 01, 2021Read more »

Hex Lok vs. Euro Thread

If you have ever had the experience of trying to connect the wrong threaded handle to a brush or squeegee head, you will know how different they are.

Or maybe you haven’t, so what is the difference?

Both thread types are suitable for the food industry and are resistant to unscrewing. Euro Thread is your typical thread type, featuring a tapered thread, and easily screws on and off. This a universal thread type and is typically quite endurable to circular motions. The Hex-Lok is a unique product with a hexagonal fitting, and an over fitting locking ring for maximum resistance.

The difference between them is the Hex-Lok solution can’t ‘unscrew’. When using deck scrubs and washing brushes, forming a pattern of ‘number 8’ is the most effective in ensuring maximum cleanliness, and how we naturally clean a surface. Often however, this loosens the end of the broom handle. While the Euro Thread has been

-

Posted: June 25, 2020Read more »

There are two types of gumboots most commonly used in the food industry: PU (polyurethane) and PVC (poly-vinyl chloride).

Gumboots made from PVC are typically cheaper than PU, but they come with trade-offs.

Here are some of the main differences:

PVC gumboots are much heavier then PU. This means you are carrying up to 1kg of extra weight with every step you take, resulting in higher levels of fatigue.

PVC gumboots typically have a lifespan 1/3 the length of PU. This means gumboots need to replaced 3 times more often.

PVC gumboots also have a greater negative impact of the environment. PVC, typically known as vinyl, causes environmental damage both during manufacture and in landfill.

Due to their shorter lifespan, and greater weight, they also contribute to a much greater amount of landfill.

A typical food processing site with 200 staff wearing gumboots could