Product Comparisons

-

Posted: February 27, 2025Read more »

In the fast-paced food industry, every second counts. Efficiency, hygiene, and cost-effectiveness are paramount, especially when it comes to something as fundamental as hand hygiene. Traditional liquid soap dispensers may seem like a simple solution, but they come with hidden costs and inefficiencies. Enter the E30 soap system—a game-changer in hand hygiene that lasts 700% longer than standard refillable dispensers while streamlining operations and reducing waste.

The Problem with Traditional Liquid Soap Dispensers

Refillable liquid soap dispensers are widely used, but they come with several downsides:- Labour Intensive: Manually refilling dispensers takes time and effort, diverting staff from critical

-

Posted: November 20, 2024Read more »

In the food industry, safety and hygiene are paramount. From handling acidic ingredients to cleaning with strong sanitizers, workers frequently encounter chemicals that could harm their skin or compromise food safety. This is where chemical-resistant gloves come into play, offering a vital layer of protection.

Understanding chemical resistance is essential for selecting gloves that balance safety, durability, and compliance. Here's what you need to know:

What is Chemical Resistance?Chemical resistance refers to a material's ability to withstand exposure to harmful substances without degradation. In gloves, it ensures the material can protect against specific chemicals without cracking, swelling, or permeating. Properly chosen gloves act as a barrier, preventing skin irritation, burns, or chemical absorption.

Importance of Chemical Resistance in the Food Industry -

Posted: July 31, 2024Read more »

In the food industry, choosing between disposable and reusable uniforms and personal protective equipment (PPE) is a decision that impacts hygiene, safety, cost, environmental sustainability, and operational efficiency. This blog explores the pros and cons of both options, providing insights into making the best choice for your business.1. The Role of Uniforms and PPE in the Food Industry

Uniforms and PPE are crucial for:Protection: Safeguarding workers from contamination and potential hazards such as sharp objects or chemical exposure.

Hygiene: Preventing contamination of food products by acting as a barrier between the worker and the food. -

Posted: May 30, 2024Read more »

The terms "X-ray detectable" and "metal detectable" refer to two different types of detection technologies used primarily in the food, pharmaceutical, and manufacturing industries to identify and eliminate contaminants. Here's an overview of the differences:

X-ray Detectable

Detection Technology: Uses X-ray imaging to detect contaminants.

Types of Contaminants Detected: Capable of identifying a wide range of contaminants, including metals, glass, stones, bones, certain plastics, and dense rubber compounds.

Detection Method: X-rays pass through the product, and the system detects differences in density between the product and potential contaminants.

Suitability: Ideal for detecting non-metallic contaminants and for products packaged in metalised films or aluminium foil.

Precision: Generally more precise in detecting small or -

Posted: February 15, 2024Read more »

The choice of glove for your production area is profuse. Commonly the thickness, colour, and material type are considered to suit your task and ingredients. But have you considered your staff's comfort?

For most staff, gloves are a non-negotiable part of their uniform. For others, however, gloves cause serious discomfort.

The most frequent complaint of reaction to gloves occurs with natural latex gloves. This allergic reaction can include rashes, blisters, and itchiness, or in severe cases – anaphylaxis.

While a rash may seem a minor complaint, reactions often intensify with continued use. There have also been situations where allergic reactions have developed over -

Posted: November 17, 2023Read more »

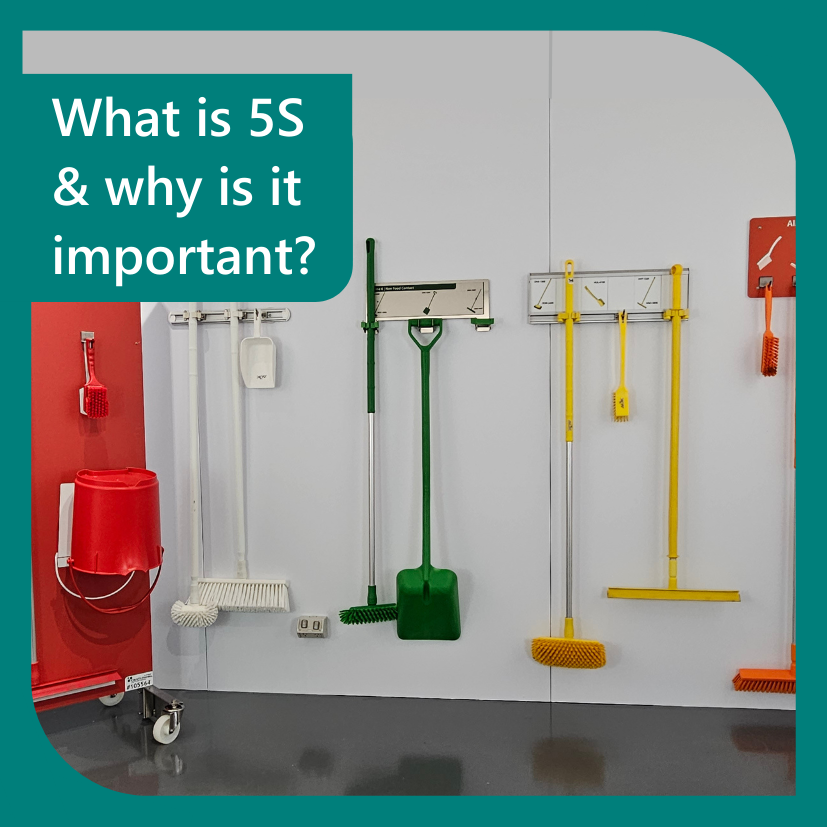

Cleaning is paramount to keeping your food and operations free from contamination, and the tools you use for this greatly impact how protected your food is. It is also key to securing audit compliance and meeting food safety standards.

However, If your tools are not stored and cared for correctly, they can become a contamination risk. This is where 5S Storage Solutions have been designed for the industry. Meaning Sort, Set, Shine, Standardise, and Sustain, it is a globally practiced storage system -

Posted: September 26, 2023Read more »

What's different about food processing Footwear?

The intense focus on hygiene within the food industry necessitates specialized footwear. The conditions in which employees work and the prolonged periods they spend on their feet dictate the need for high-quality boots.

Selecting the appropriate footwear offers numerous benefits, such as increased employee satisfaction, reduced slip-related injuries and complaints, enhanced productivity, and minimized hygiene-related risks.

In food processing, the primary types of footwear are gumboots and leather shoes. The attributes that make these shoes suitable for the food industry include:

Leather Footwear Considerations:

Elastic vs. laced designs play a crucial role. Some facilities prohibit shoelaces due to the contamination risk they pose, especially when walkways or platforms exist above production lines.

-

Posted: September 15, 2023Read more »

Where do I start with colour coding?

What are the non-negotiable contamination risks you need to prevent? It’s these areas that are ideal to begin managing using colour. There’s no right or wrong way to do this, and colour coding is fully customisable to your needs.

Outlined below are some of the common colour coding practices used within the industry. If you are interested in how and why it works, click through to this blog where we outline some tips on implementing it.

Allergen management:

Allergen contamination is a universal concern within the food processing industry, as the consequence of this occurring is -

Posted: September 04, 2023Read more »

Blue is associated as the food industry colour, as it contrasts the majority of ingredients.

This, of course allows visual detection in the unlikely case of it falling into production. However, the use of coloured PPE has increased within the industry to manage contamination and hygiene risks, with no change to PPE quality or cost.

So, why not just use blue?

Reputational damage from a cross-contamination event is just not an option, not to mention the cost of this on your business. While blue allows for easier foreign object traceability, it doesn’t safe-guard from the possibility of mis-handling product, for example allergens.

This is where colour coded PPE comes in. -

Posted: May 30, 2023Categories: Product ComparisonsRead more »

In the food industry, safety is paramount, and hand protection is no exception. Cut-resistant gloves are a critical component in ensuring worker safety. But with so many ratings and standards out there, it can become confusing to navigate and understand them all. In this blog post, we aim to simplify and explain the different cut ratings and standards, both old and new, that dictate the level of protection offered by cut-resistant gloves.

Understanding Cut Ratings and Standards

Before diving into specifics, it's essential to understand what cut ratings are and why they matter. In simple terms, cut ratings indicate the level of cut resistance offered by a glove. Higher cut ratings mean that the gloves offer better protection against cuts. These ratings are standardized by various bodies, each with different testing methods and rating systems.

1. EN388 (European Standard)The EN388 standard is a popular and widely