minimize cross-contamination

-

Posted: January 10, 2020Read more »

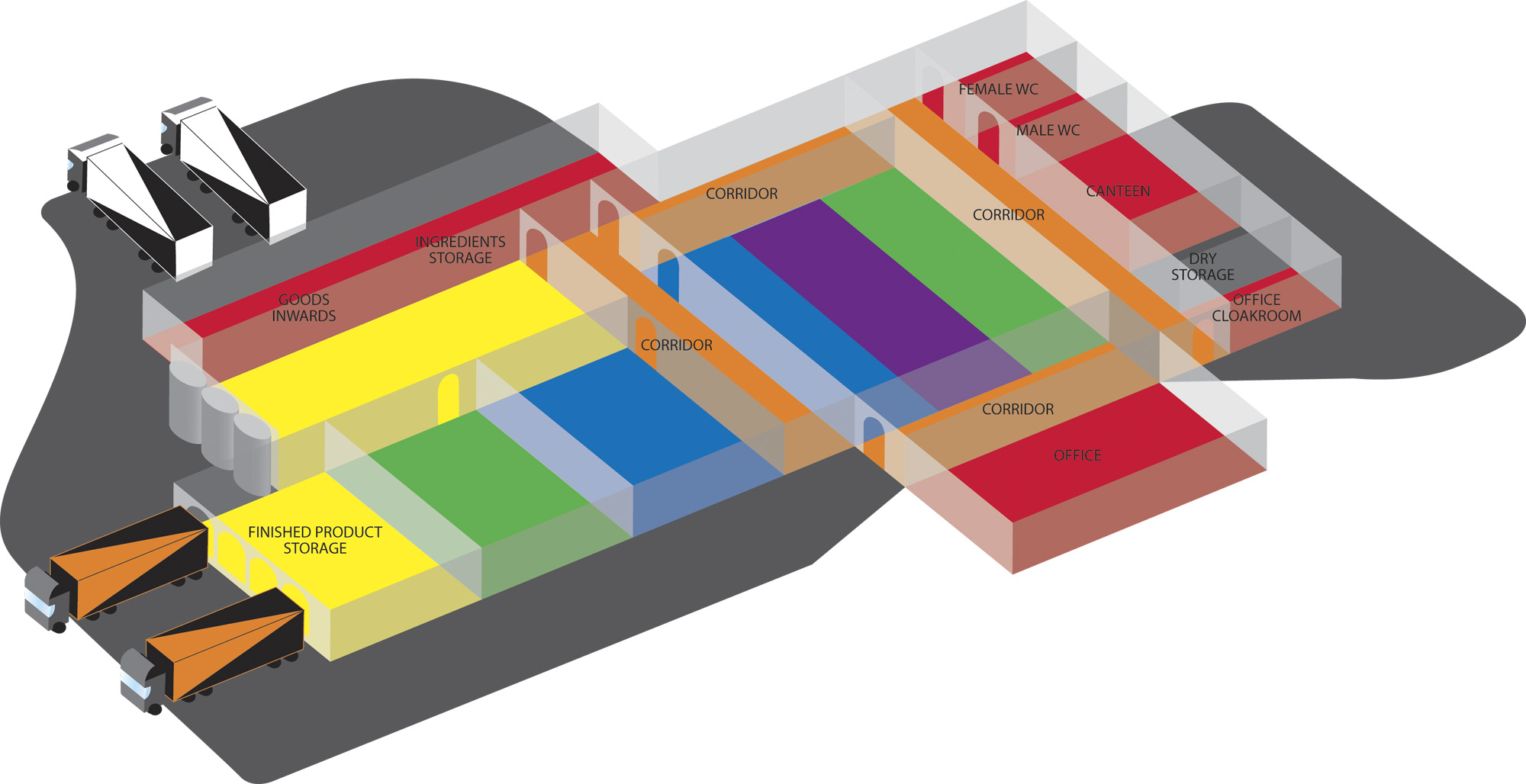

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility.

While not always a requirement, color-coding can demonstrate a company’s commitment to the quality and consistency of their products while maintaining a high level of safety for both their employees and consumers. It can be implemented to provide ‘zone control’ within a food processing or food service facility. Different colours can be assigned to each step in the process or by manufactory lines. When the colours are assigned to zones, confirming that a tool is misplaced is easy and tracing it back to its point of origination is quick.

1. Keep it simple - Limit the number of colours you use to keep it as simple as possible.

2. Pick contrasting colours - Red colour coded equipment is often associated and used with raw/uncooked meats. However, being aware of the potential problems

- Colour Coded Hygiene (17)

- Metal Detection (4)

- Food processing products (33)

- Product Comparisons (31)

- Food Safety (18)

- Procurement (11)

- 5S (5)