What colours should I use to colour code my food production facility?

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility.

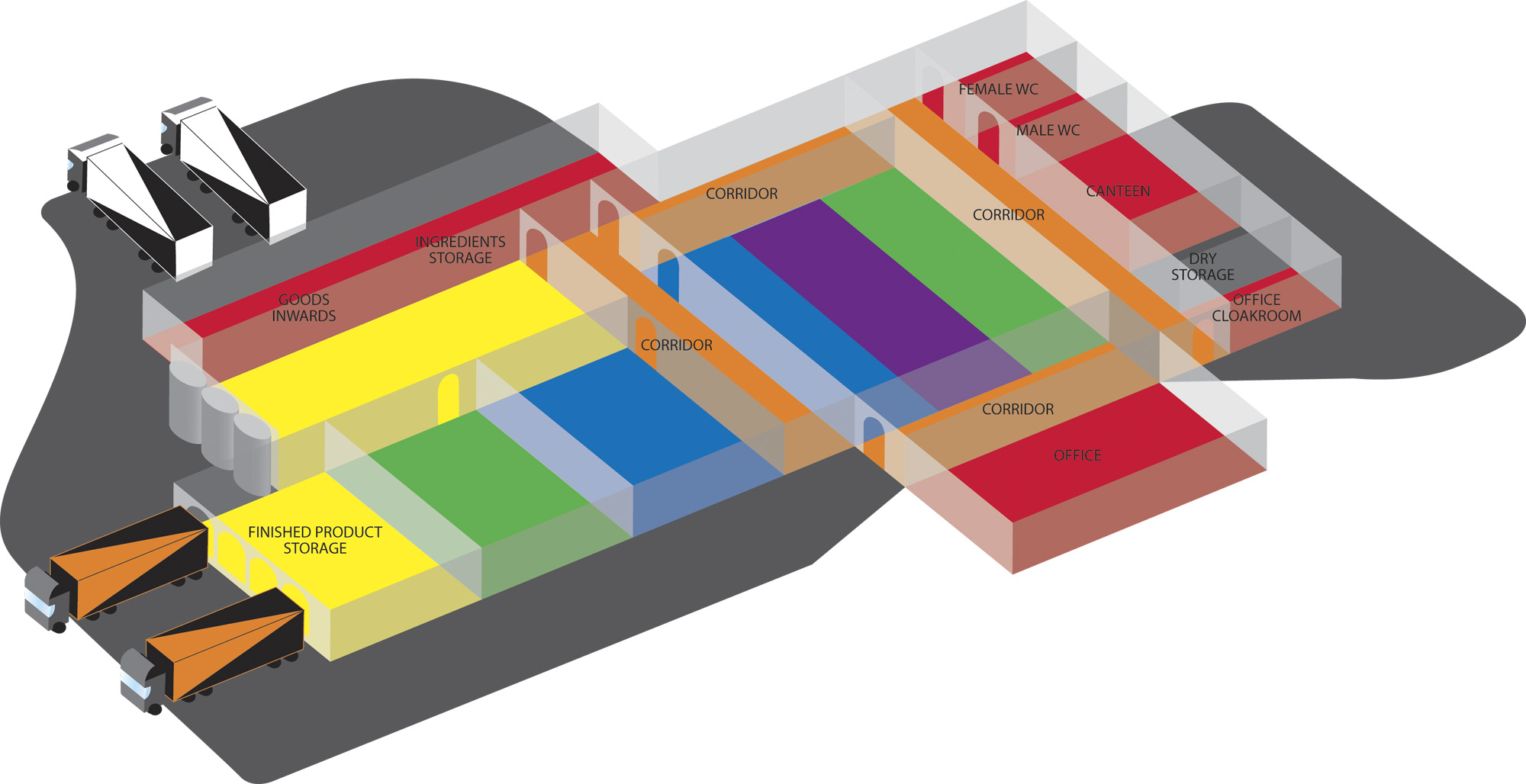

While not always a requirement, color-coding can demonstrate a company’s commitment to the quality and consistency of their products while maintaining a high level of safety for both their employees and consumers. It can be implemented to provide ‘zone control’ within a food processing or food service facility. Different colours can be assigned to each step in the process or by manufactory lines. When the colours are assigned to zones, confirming that a tool is misplaced is easy and tracing it back to its point of origination is quick.

1. Keep it simple - Limit the number of colours you use to keep it as simple as possible.

2. Pick contrasting colours - Red colour coded equipment is often associated and used with raw/uncooked meats. However, being aware of the potential problems this may present; a tool being dropped into the product being worked on, and not easily spotted, could mean the difference between a simple fixable mistake and a pricey recall.

3. Avoid complicated colour assignments - Instant recognition is an effective benefit of colour coded systems, as it takes away complications of tool mix-ups. To aid this, having the same colour handle and sweeper, squeegee or mop head is suggested.

4. Roll out the program all at once - This will help in avoiding confusion. Make all tool changes at one time, along with a training session for staff and an announced start date for the new transition.

5. Use signage for reinforcement - To remind workers of colours and their assigned zones, signage solutions are available.

Making the decision to apply colour coding

Consider the HACCP (Hazard Analysis and Critical Control Points) guidelines; which is a risk assessment measure used to manage potential food safety risks. After weighting the benefits, proactive steps taken by many food processors include instituting the colour coding plan as a practice.

Developing a colour coded plan

1. Conduct a comprehensive hazard analysis: are there any areas in your facility where there is a chance of allergen cross contamination or cross contact?

2. Evaluate of applicability of colour coding: will colour coding prevent issues? if you are needing a way to identify equipment for their application as a preventative control, colour coding would be appropriate.

3. Establish control measures, preventative controls and practices: may be put in place as good manufacturing practices, risk-based preventative control or as an industry best practice.

4. Set the monitoring, corrective action, verification, and review criteria for the plan: ensuring the correct coloured equipment in areas can be effectively viewed, allowing easy corrective actions to be put in place.

5. Education, train and refresh the employees on the plan: ensure all workers are aware of the plan

Deciding which products to colour code

Uniform (aprons/footwear/beard nets/hairnets) – identify workers of different areas easily and minimise pathogen contamination spreading

Bins/tubs/containers/crates – identify and separate waste from edible products

Hygiene equipment (scoops/sweepers/squeegees) – keeps tools from spreading one type of contamination or allergen to other areas in the plant