Colour Coded Hygiene

-

Posted: July 31, 2024Read more »

In the food industry, choosing between disposable and reusable uniforms and personal protective equipment (PPE) is a decision that impacts hygiene, safety, cost, environmental sustainability, and operational efficiency. This blog explores the pros and cons of both options, providing insights into making the best choice for your business.1. The Role of Uniforms and PPE in the Food Industry

Uniforms and PPE are crucial for:Protection: Safeguarding workers from contamination and potential hazards such as sharp objects or chemical exposure.

Hygiene: Preventing contamination of food products by acting as a barrier between the worker and the food. -

Posted: November 17, 2023Read more »

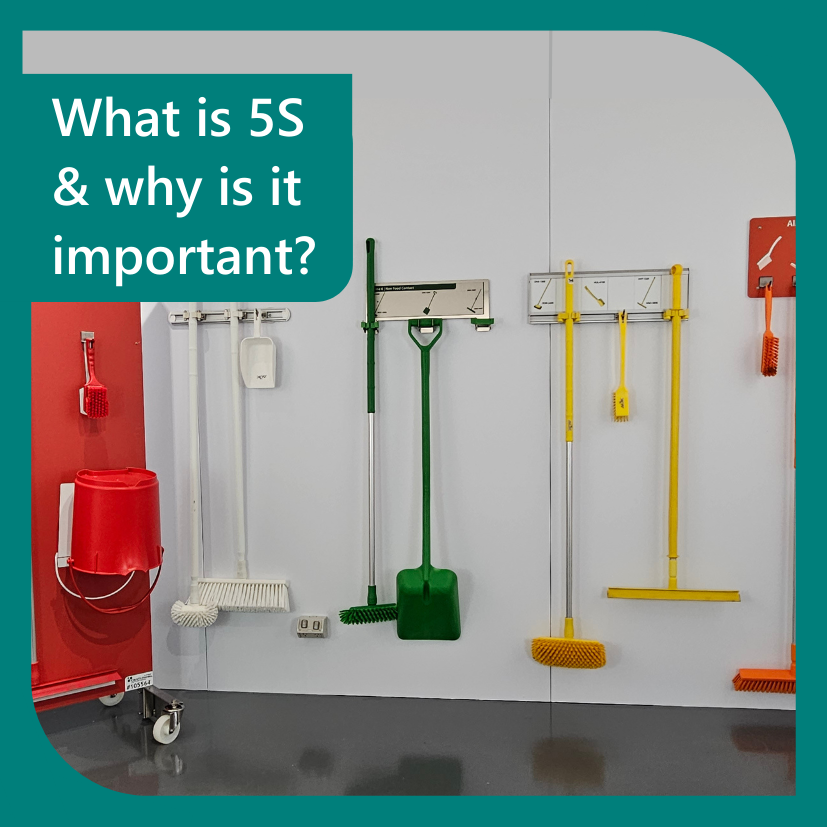

Cleaning is paramount to keeping your food and operations free from contamination, and the tools you use for this greatly impact how protected your food is. It is also key to securing audit compliance and meeting food safety standards.

However, If your tools are not stored and cared for correctly, they can become a contamination risk. This is where 5S Storage Solutions have been designed for the industry. Meaning Sort, Set, Shine, Standardise, and Sustain, it is a globally practiced storage system -

Posted: September 15, 2023Read more »

Where do I start with colour coding?

What are the non-negotiable contamination risks you need to prevent? It’s these areas that are ideal to begin managing using colour. There’s no right or wrong way to do this, and colour coding is fully customisable to your needs.

Outlined below are some of the common colour coding practices used within the industry. If you are interested in how and why it works, click through to this blog where we outline some tips on implementing it.

Allergen management:

Allergen contamination is a universal concern within the food processing industry, as the consequence of this occurring is -

Posted: September 04, 2023Read more »

Blue is associated as the food industry colour, as it contrasts the majority of ingredients.

This, of course allows visual detection in the unlikely case of it falling into production. However, the use of coloured PPE has increased within the industry to manage contamination and hygiene risks, with no change to PPE quality or cost.

So, why not just use blue?

Reputational damage from a cross-contamination event is just not an option, not to mention the cost of this on your business. While blue allows for easier foreign object traceability, it doesn’t safe-guard from the possibility of mis-handling product, for example allergens.

This is where colour coded PPE comes in. -

Posted: February 10, 2023Read more »

In the food processing industry, colour coding is an effective way to prevent cross-contamination and reduce the risk of allergen exposure.

Designating a specific colour to different ingredients or parts of the process allows employees to identify and maintain food safety standards quickly.When deciding which colours to use, it's important to start by identifying which ingredients require segregation. For example, if you have allergens such as nuts or gluten in your food processing site, it's important to consider the colour

-

Posted: September 12, 2022Read more »

PPE and Hygiene are indispensable in the food processing industry. The purpose of hygiene wear and PPE are quite different to one another; hygiene wear is disposable clothing designed to keep the food free from contamination; protecting the task from the wearer whereas PPE protects the wearer from the task. These products can occasionally satisfy both purposes. For instance, a disposable poncho protects the wearer from splashes while preventing matter from falling off their clothes.

Colour, as we know, plays a critical role in preventing cross-contamination and controlling allergens. Most hygiene wear is available in blue and or white, but many come in additional colours such as red, yellow, and green. Purple, pink, orange and black are unique colours and can further signify different roles or tasks.

It is crucial, however, not to overcomplicate your colour-coded system. Colour coding works due to its quick visual recognition and ease of interpretation - particularly

-

Posted: August 15, 2022Read more »

Hygiene wear is available in many forms within the food processing industry. Keeping the food pure and uncontaminated is of utmost importance. Labcoats are an indispensable product to ensure food is protected.

Labcoats act as a hygiene barrier between clothing and the task at hand. Many food production sites mandate labcoats. However, it’s hard to know which is preferable, disposable, or reusable. While both have advantages, the primary purpose is the same. It comes down to whether you prefer to purchase a uniform for your team members and are willing to launder it or choose to have disposable lab coats which cover your team’s usual clothes.

With disposable wear, don’t forget to purchase larger sizing to account for regular clothing underneath. Labcoats are designed to be efficiently made, so shaping is limited, this means bigger sizes can be comfortably worn.

The primary purpose

-

Posted: May 09, 2022Categories: Colour Coded HygieneRead more »

Keeping the floor clean is a challenge many companies face. No matter how proactive and the number of measures implemented, the floors still need to be cleaned frequently. Mops have evolved from the traditional string-mop and bucket to modern microfibre continuous stringed or flat mops. While mops have advanced over the years, the old traditional styles remain available.

So which options best suit your production area?

Ideally your mop should be an effective floor cleaner and needs to be made from an absorbent durable material. The strands should be continuous or should not come loose. It should be ergonomic and finally, either disposable or easy to clean.

The string mop concept, although old, is still current. They were originally made of strands, often old cloths, or strings tied together. They are now made from a continuous microfibre strand, designed not to fall apart, while being increasingly absorbent. A strand mop, which refers to strands

-

Posted: March 21, 2022Read more »

Necessity, as the old saying goes, is the mother of invention.

Food processors had a need, and Sanifix was created as the solution.

It is a unique system specifically designed for the food processing industry and the challenges involved in storage and dispensing.

It solves multiple auditing issues that regularly arise regarding holes in walls, and the hygiene and safety concerns this causes.

The main aim of the Sanifix system is to remove the need to penetrate into the walls of production facilities.But first, why are holes an issue?

Most food processing facilities use coolroom panel (or EPS) for walls due to its excellent insulation and ease to wash down. In a processing plant, space is valuable, and often cleaning equipment is stored on the wall out of the way. However, when attaching these to the wall, the most common method was using screws, and these caused holes in the wall. This then created further issues,

-

Posted: February 07, 2022Read more »

Let’s face it, cleanliness is a priority in the food processing industry. While some foods are classified as high risks, such as meat and dairy products; hygiene is essential in all food production areas. The best way to achieve a high standard of cleanliness is through having quality cleaning products. There are a few things that characterise quality, such as:

- the material

- the ergonomics

- the colour varieties

- the endurance

- and the effectiveness

Cleaning product that feature these attributes are