Metal Detection

-

Posted: May 30, 2024Read more »

The terms "X-ray detectable" and "metal detectable" refer to two different types of detection technologies used primarily in the food, pharmaceutical, and manufacturing industries to identify and eliminate contaminants. Here's an overview of the differences:

X-ray Detectable

Detection Technology: Uses X-ray imaging to detect contaminants.

Types of Contaminants Detected: Capable of identifying a wide range of contaminants, including metals, glass, stones, bones, certain plastics, and dense rubber compounds.

Detection Method: X-rays pass through the product, and the system detects differences in density between the product and potential contaminants.

Suitability: Ideal for detecting non-metallic contaminants and for products packaged in metalised films or aluminium foil.

Precision: Generally more precise in detecting small or -

Posted: October 04, 2022Read more »

Metal detectable products are becoming increasingly common within the food industry, It is essential to understand the different features and how they can impact you. As always, the priority is ensuring the highest standards of safety are maintained. Pen features vary significantly, so choosing the right pen to suit your needs is essential.

Here are some factors you need to consider when selecting your metal detectable stationery.

Is the most detectable pen the best option?

While it may sound counterintuitive, the pen made from the most detectable plastic might not be the best option. Small amounts of ferrous material are added to the plastic mix to make plastic detectable. Simply put, the higher the ferrous material in the mix, the more detectable the plastic is. However, this both makes the

-

Posted: December 09, 2020Categories: Metal DetectionRead more »

Metal detection systems have become an integral part of the foreign body prevention process in food processing facilities.

Possibly nowhere is product integrity more important than in food and beverage production. As well as continuous improvement teams, technical and quality personnel are constantly looking for ways to reduce ‘foreign body’ and contamination risks. With metal being one of the most frequent offenders, leading food and pharmaceutical manufacturers have for a long time used specialist metal detectors to control this risk.

A simplified look at how this works:

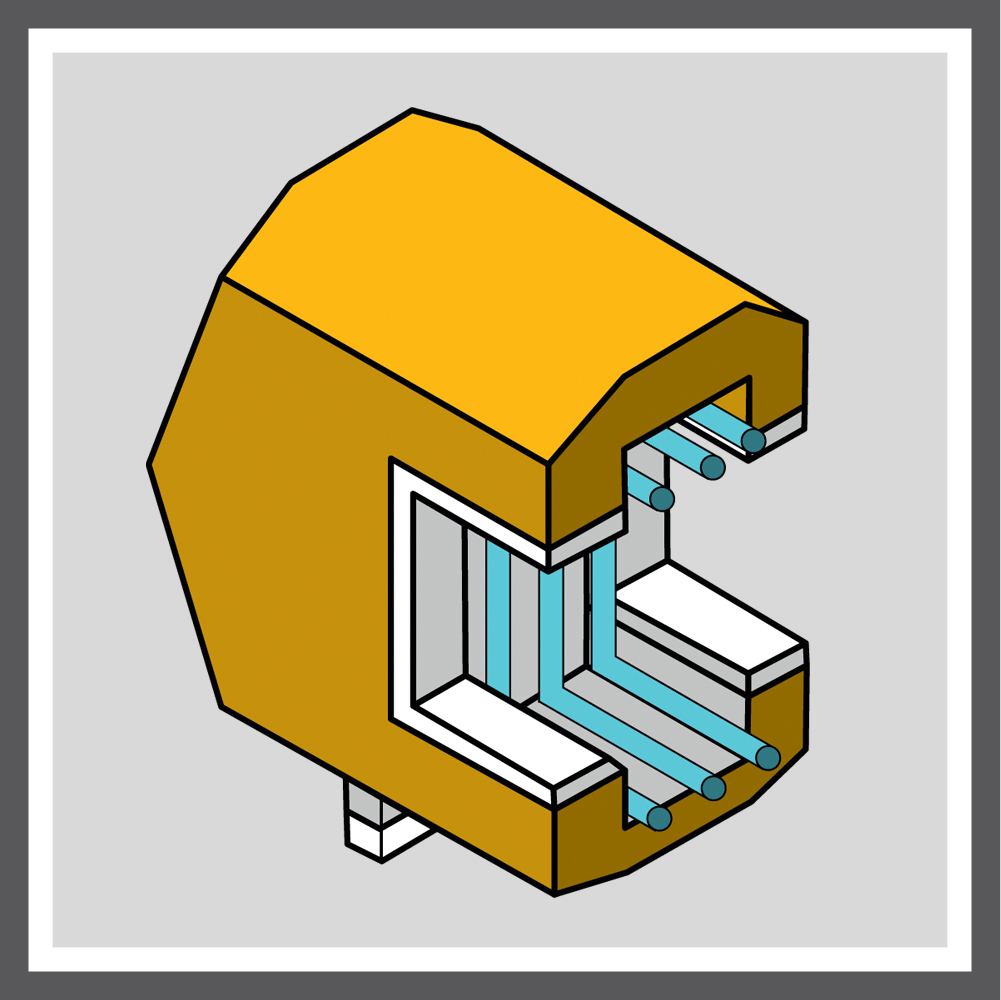

1. The most common metal detectors are based on a balanced coil design.

2. This involves passing the product through three coils.

3. The middle coil acts as the transmitter by using an electrical current to create a magnetic field.

4. The transmitter induces a current in the other two coils, which are spaced equidistant from the middle coil. The outside

-

Posted: September 28, 2020Categories: Metal DetectionRead more »

When setting up your metal detector, your core variable is the metal detector frequency. Here we look at 7 other factors you need to take into account.

1. Product characteristics

Every product creates a ‘background signal’. Don’t worry – this is not metal in your product, just characteristics which behave the same as metal when going through the detector! Food stuffs loosely fall into two categories – “dry product” and “wet product”. Dry products (eg, dried pasta, snacks) create a much lower background signal. By contrast, wet products (eg dairy, ready meals) create a much higher signal. If the detector frequency is too high, the background signal will trigger your detector. As a result, product will be falsely rejected.

TIP: Find out the background signal of your products – run them through the detector, increasing the frequency until it starts rejecting product.

2. Metal type