food and beverage production

-

Posted: December 09, 2020Categories: Metal DetectionRead more »

Metal detection systems have become an integral part of the foreign body prevention process in food processing facilities.

Possibly nowhere is product integrity more important than in food and beverage production. As well as continuous improvement teams, technical and quality personnel are constantly looking for ways to reduce ‘foreign body’ and contamination risks. With metal being one of the most frequent offenders, leading food and pharmaceutical manufacturers have for a long time used specialist metal detectors to control this risk.

A simplified look at how this works:

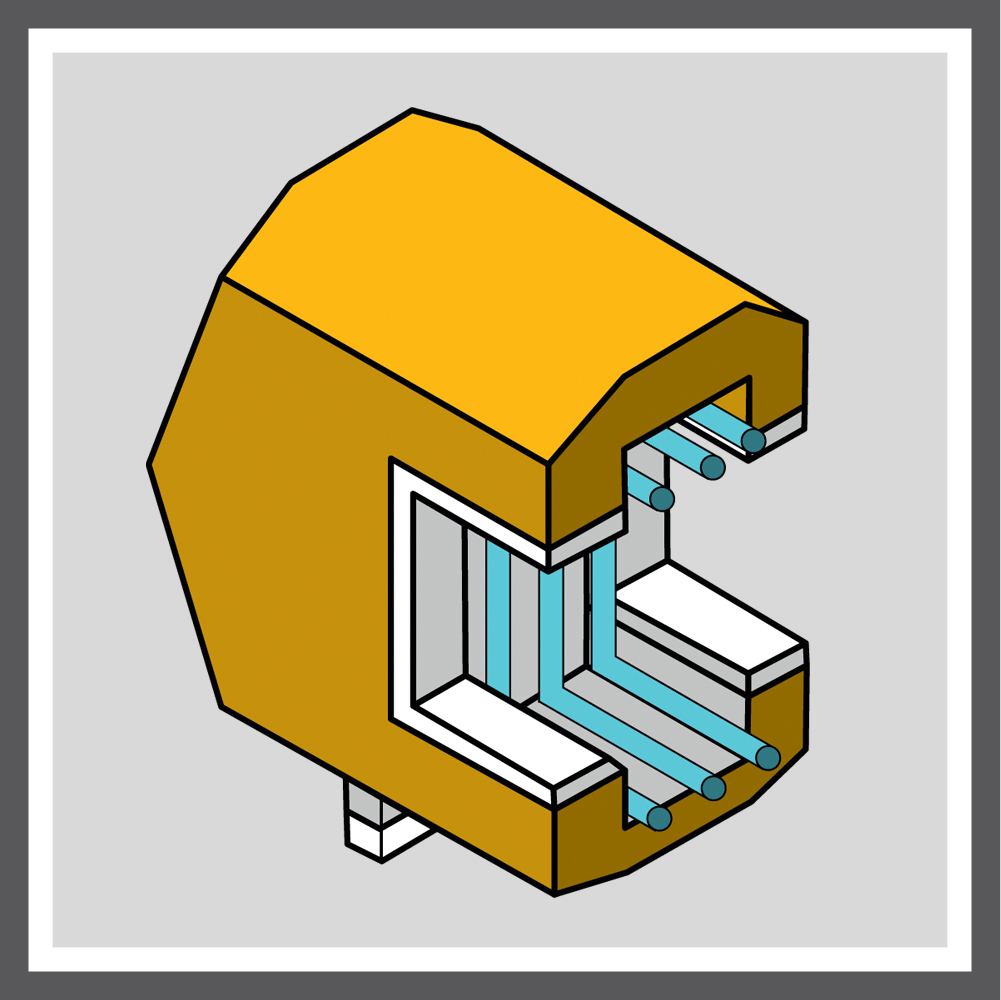

1. The most common metal detectors are based on a balanced coil design.

2. This involves passing the product through three coils.

3. The middle coil acts as the transmitter by using an electrical current to create a magnetic field.

4. The transmitter induces a current in the other two coils, which are spaced equidistant from the middle coil. The outside

- Colour Coded Hygiene (17)

- Metal Detection (4)

- Food processing products (33)

- Product Comparisons (31)

- Food Safety (18)

- Procurement (11)

- 5S (5)