colour coding

-

Posted: September 15, 2023Read more »

Where do I start with colour coding?

What are the non-negotiable contamination risks you need to prevent? It’s these areas that are ideal to begin managing using colour. There’s no right or wrong way to do this, and colour coding is fully customisable to your needs.

Outlined below are some of the common colour coding practices used within the industry. If you are interested in how and why it works, click through to this blog where we outline some tips on implementing it.

Allergen management:

Allergen contamination is a universal concern within the food processing industry, as the consequence of this occurring is -

Posted: January 10, 2020Read more »

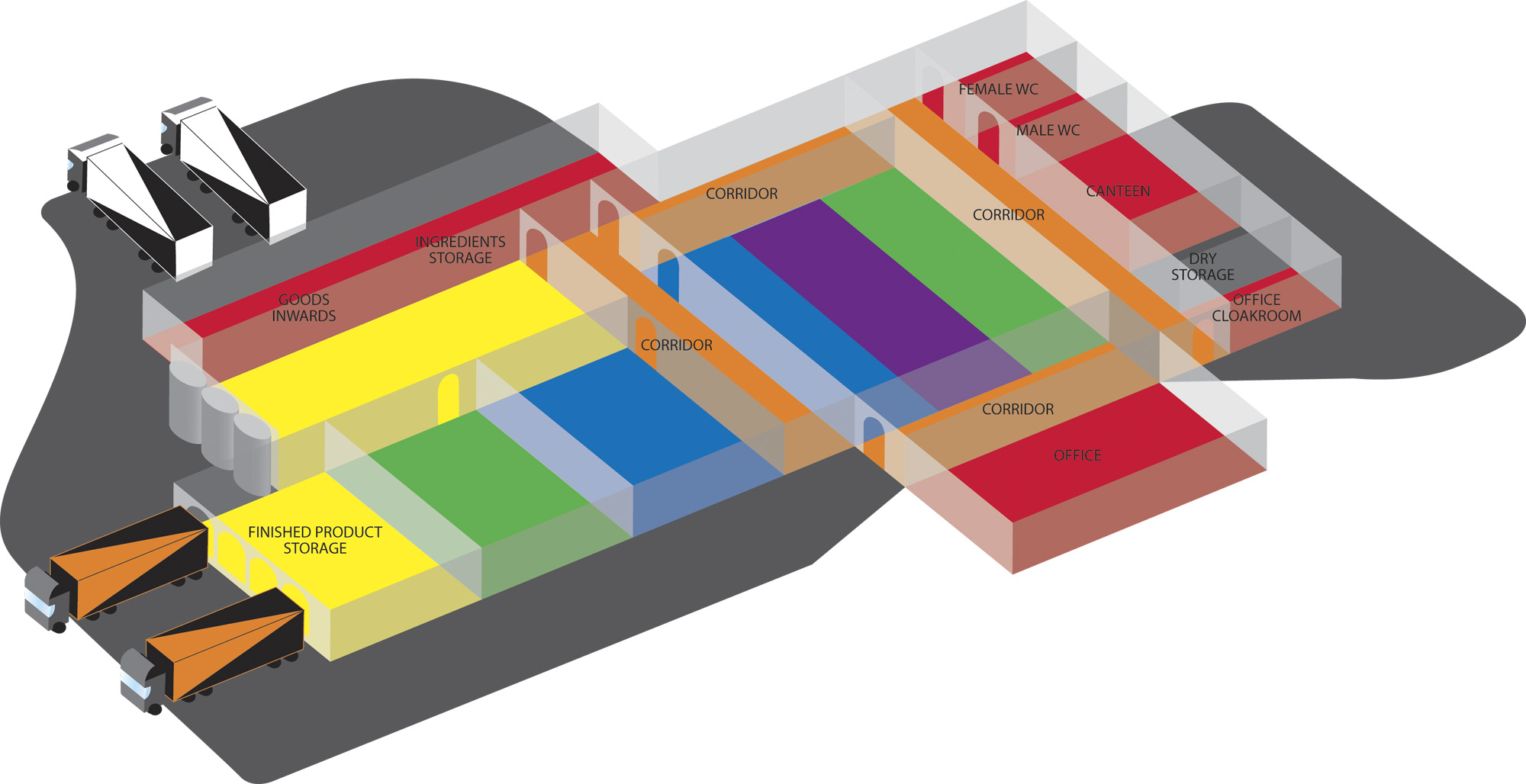

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility.

While not always a requirement, color-coding can demonstrate a company’s commitment to the quality and consistency of their products while maintaining a high level of safety for both their employees and consumers. It can be implemented to provide ‘zone control’ within a food processing or food service facility. Different colours can be assigned to each step in the process or by manufactory lines. When the colours are assigned to zones, confirming that a tool is misplaced is easy and tracing it back to its point of origination is quick.

1. Keep it simple - Limit the number of colours you use to keep it as simple as possible.

2. Pick contrasting colours - Red colour coded equipment is often associated and used with raw/uncooked meats. However, being aware of the potential problems