Blog

-

March 28, 2024

Consolidation.

Anyone familiar with purchasing consumables would understand the complexities of ensuring quality products are always available before they are required.

Complexities include the stress of managing multiple suppliers, invoices, deliveries, and backorders, as well as monitoring stock levels whilst also balancing the demand for cost efficiencies with the high-quality standards food processing mandates.

The solution? Consolidation.

Many Corporations use their buying power to navigate contracts and tenders. Consolidation

-

February 15, 2024

The choice of glove for your production area is profuse. Commonly the thickness, colour, and material type are considered to suit your task and ingredients. But have you considered your staff's comfort?

For most staff, gloves are a non-negotiable part of their uniform. For others, however, gloves cause serious discomfort.

The most frequent complaint of reaction to gloves occurs with natural latex gloves. This allergic reaction can include rashes, blisters, and itchiness, or in severe cases – anaphylaxis.

While a rash may seem a minor complaint, reactions often intensify with continued use. There have also been situations where allergic reactions have developed over t -

January 17, 2024

The benefit of an account : pricing.

At Foodcare, we value our partnership with our customers belonging to the food and beverage manufacturing industry. As our products and services are dedicated to this industry alone, we offer special pricing across our full range to anyone belonging to the industry. For our longer-standing customers, further price deductions may be arranged with their sales rep.

So, how do you access your correct pricing?

Simply log into your account on our website or create one if you haven’t yet. This will automatically sync to your correct pricing. (New accounts may take a standard business day to be activated.)

If you are not logged in, you will not be accessing our trade pricing, or other agreed upon pricing.

Furthermore, pricing on products varies from time to time. To ensure you have current pricing, i -

November 17, 2023

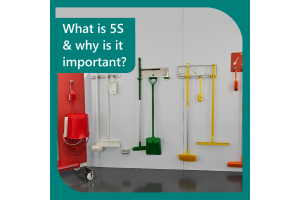

Cleaning is paramount to keeping your food and operations free from contamination, and the tools you use for this greatly impact how protected your food is. It is also key to securing audit compliance and meeting food safety standards.

However, If your tools are not stored and cared for correctly, they can become a contamination risk. This is where 5S Storage Solutions have been designed for the industry. Meaning Sort, Set, Shine, Standardise, and Sustain, it is a globally practiced storage system -

September 15, 2023

Where do I start with colour coding?

What are the non-negotiable contamination risks you need to prevent? It’s these areas that are ideal to begin managing using colour. There’s no right or wrong way to do this, and colour coding is fully customisable to your needs.

Outlined below are some of the common colour coding practices used within the industry. If you are interested in how and why it works, click through to this blog where we outline some tips on implementing it.

Allergen management:

Allergen contamination is a universal concern within the food processing industry, as the consequence of this occurring is -

September 04, 2023

Blue is associated as the food industry colour, as it contrasts the majority of ingredients.

This, of course allows visual detection in the unlikely case of it falling into production. However, the use of coloured PPE has increased within the industry to manage contamination and hygiene risks, with no change to PPE quality or cost.

So, why not just use blue?

Reputational damage from a cross-contamination event is just not an option, not to mention the cost of this on your business. While blue allows for easier foreign object traceability, it doesn’t safe-guard from the possibility of mis-handling product, for example allergens.

This is where colour coded PPE comes in. -

May 31, 2023

Adopting effective methods to detect and prevent foreign contaminants from entering the food supply chain is crucial for the food processing industry. Metal contaminants, such as broken machinery parts or small, and other foreign objects pose a significant risk to consumer health and can damage brand’s reputation. To mitigate these risks, food processors rely on advanced technologies like metal detection and X-ray inspection systems. Outlined below are the differences between metal-detectable and X-ray methods, highlighting their unique capabilities and applications in ensuring food safety.

Metal Detectable:

Metal detection systems are common throughout the industry, providing a reliable means of identifying and removing metallic contaminants from food products. These systems use electromagnetic fields to detect the presence of ferrous, non-ferrous, and stainless-steel metals. Smaller objects that are unavoidable around the production area s

-

May 30, 2023

In the food industry, safety is paramount, and hand protection is no exception. Cut-resistant gloves are a critical component in ensuring worker safety. But with so many ratings and standards out there, it can become confusing to navigate and understand them all. In this blog post, we aim to simplify and explain the different cut ratings and standards, both old and new, that dictate the level of protection offered by cut-resistant gloves.

Understanding Cut Ratings and Standards

Before diving into specifics, it's essential to understand what cut ratings are and why they matter. In simple terms, cut ratings indicate the level of cut resistance offered by a glove. Higher cut ratings mean that the gloves offer better protection against cuts. These ratings are standardized by various bodies, each with different testing methods and rating systems.

1. EN388 (European Standard)The EN388 standard is a popular and widely

-

April 26, 2023

Could your waste be of value?

Efficiency and time are crucial factors for the success of any production site, to meet efficiency standards while reducing environmental impact. Although waste is an inevitable by-product of production, utilizing coloured bin liners allows for more efficient management and disposal of waste.

How can coloured bin liners help?

Colour coding has proven successful throughout the industry, as its quick visual recognition allows employees to speedily distinguish between ingredients. This prevents any potential health hazards such as cross-contamination. Coloured bin liners could be utilised in this same way. For example, to segregate ingredients that can be reused, recycled, composted, or that are potentially harmful.

-

March 23, 2023

A food processing plant has one of the highest responsibilities to maintain hygiene standards, which promotes the need for both spontaneous and deep, regular cleaning. Wipes are part of both these processes and are indispensable to the food processing industry.

How do I get the full benefit out of my wipes? It is first important to consider what situation your wipes are used in. Considering the machinery, surfaces, chemicals, and ingredients will clarify which spec suits your needs.

Material composition and absorbency

A wipe is made from a combination of synthetic fibres and either paper or viscose. The synthetic fibres give the wipe strength and allow the wipe to hold its shape, whereas the paper or viscose (wood pulp turned into fabric) increases the absorbency. Therefore,