cross contamination

-

Posted: February 10, 2023Read more »

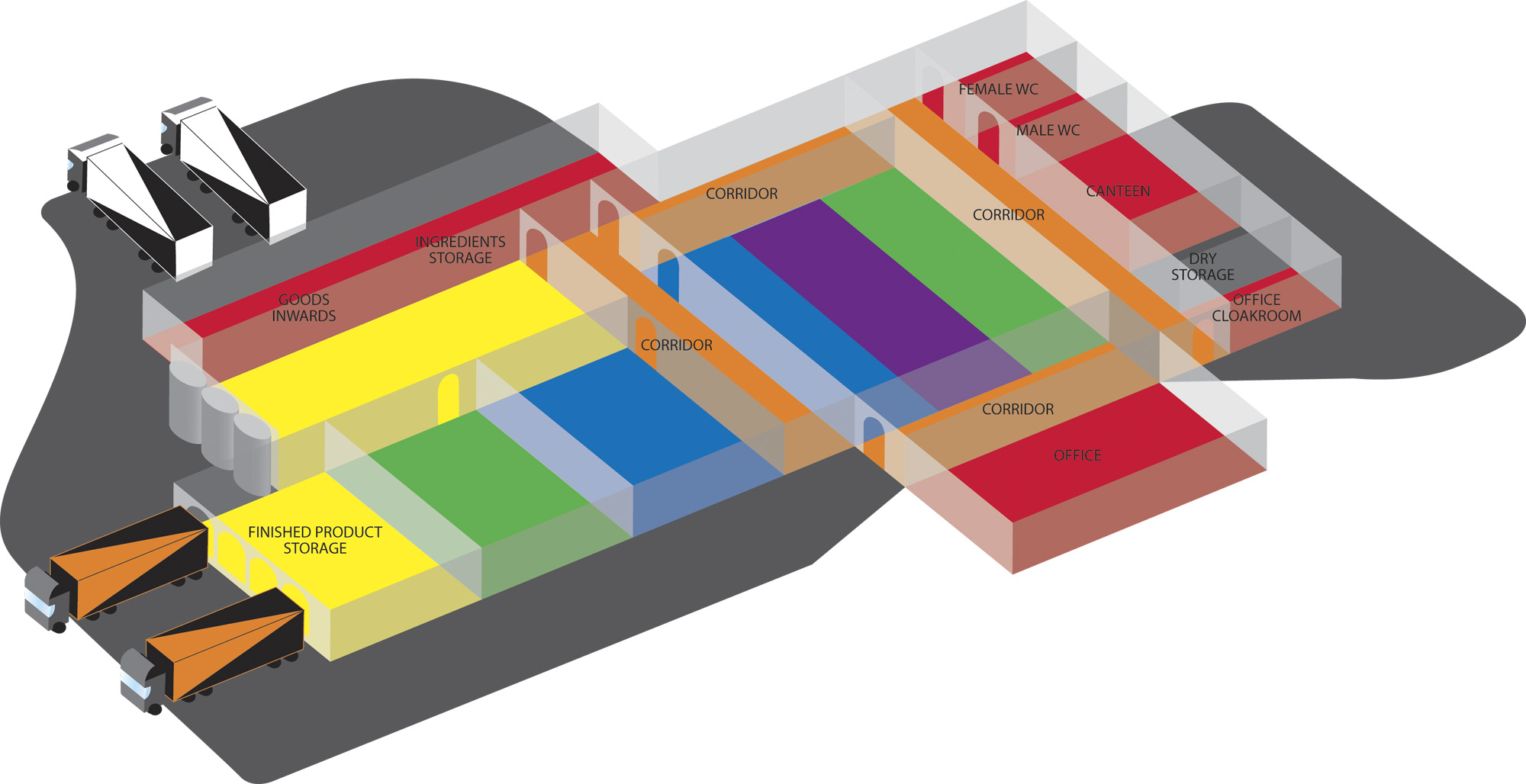

In the food processing industry, colour coding is an effective way to prevent cross-contamination and reduce the risk of allergen exposure.

Designating a specific colour to different ingredients or parts of the process allows employees to identify and maintain food safety standards quickly.When deciding which colours to use, it's important to start by identifying which ingredients require segregation. For example, if you have allergens such as nuts or gluten in your food processing site, it's important to consider the colour

-

Posted: January 10, 2020Read more »

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility.

While not always a requirement, color-coding can demonstrate a company’s commitment to the quality and consistency of their products while maintaining a high level of safety for both their employees and consumers. It can be implemented to provide ‘zone control’ within a food processing or food service facility. Different colours can be assigned to each step in the process or by manufactory lines. When the colours are assigned to zones, confirming that a tool is misplaced is easy and tracing it back to its point of origination is quick.

1. Keep it simple - Limit the number of colours you use to keep it as simple as possible.

2. Pick contrasting colours - Red colour coded equipment is often associated and used with raw/uncooked meats. However, being aware of the potential problems