5s

-

Posted: November 17, 2023Read more »

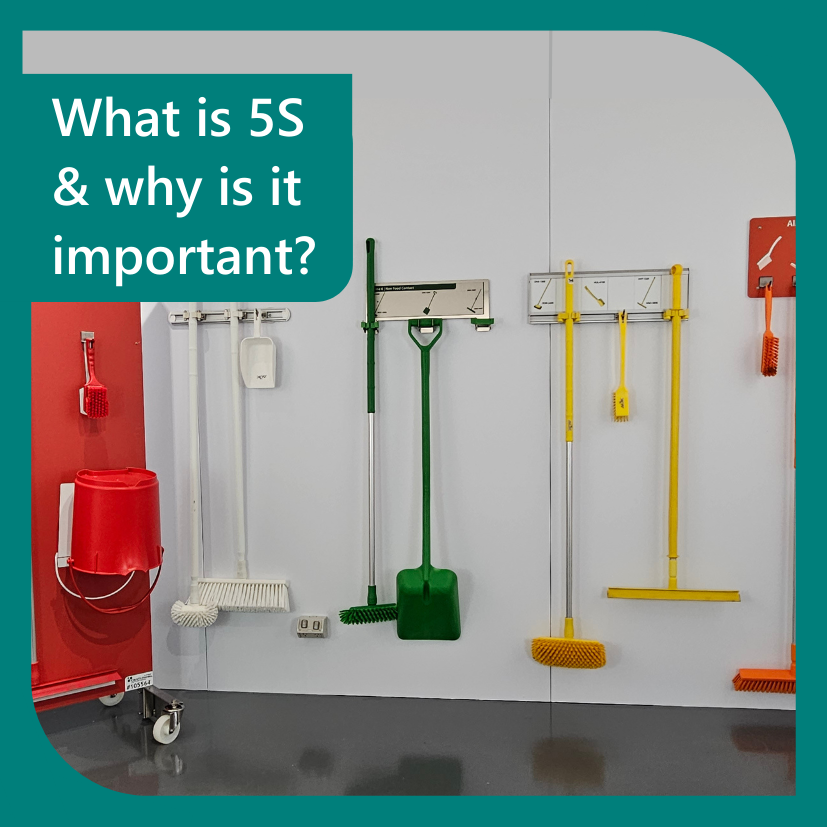

Cleaning is paramount to keeping your food and operations free from contamination, and the tools you use for this greatly impact how protected your food is. It is also key to securing audit compliance and meeting food safety standards.

However, If your tools are not stored and cared for correctly, they can become a contamination risk. This is where 5S Storage Solutions have been designed for the industry. Meaning Sort, Set, Shine, Standardise, and Sustain, it is a globally practiced storage system -

Posted: January 20, 2020Read more »

Implementing a 5S system in your food processing facility may seem like a daunting task.

While there a many factors to be considered, and decisions to be made, making a start doesn’t need to be difficult.

Below is a simple checklist you can use to begin the process of implementing a 5S storage solution for your cleaning equipment.

It will give you an idea of what stage you are at, and what decisions will need to be made before beginning implementation.

Do you currently have a colour code plan for your site (by area/allergen/process)?

Yes No Comments:Do you have a documented colour code plan that segregates different areas, products, or allergens? It is important to have this confirmed before going much further so that there aren’t changes later on to the colours you are using in each area.

Do

-

Posted: December 02, 2019Read more »

The Identi-Rail system is designed to make 5S implementation easy for food processors.

The modular system means:

-every station is entirely customised

-changes can be easily made to tool requirements

-a 5S system can be implemented then improved over time

Get in touch with one of the team to learn more about the range of 5S cleaning tool storage systems available.