Colour Coded Hygiene

-

Posted: November 15, 2021Read more »

Buckets and pails are very familiar products, but they are often confused with one and another. However, there is a difference, and that main difference is the purpose.

Bucket is the more familiar term. It is a cylindrical upright open container with a handle. The primary purpose of a bucket is to transport liquids and that is why they are popular in the food industry. In addition to carrying liquids such as water and milk they are also used to carry bulk dry ingredients such as flour, sugar and spices. They can also be used for cleaning and carrying chemicals. They are designed to be a quick efficient way or transporting liquids or solids in reasonable sized quantities. Some buckets may come with lids, this additional feature is favourable to ensure the safety of your produce short term.

A pail, although having the same cylindrical appearance, is designed to be used for storage. One of the big differences is a pail usually has an air-tight or a tamper-proof

-

Posted: May 17, 2021Read more »

Bins, buckets and containers are designed for the transportation and storage of goods. They are commonly used in the food industry for the bulk storage for ingredients and other produce. The food industry’s high standard of hygiene requires specially designed products to minimize any risk, particularly for products that have contact with food. To ensure your storage methods are suitable and food safe, see below key features of bins, buckets and containers specifically designed for the food industry.

- Round edges – in the food industry all sharp edges are minimized to prevent mold and bacterial build up. These sharp angles are extremely difficult to clean sufficiently. It is vital to prevent all mold and contamination that may grow in grooves and edges, particularly in contact with food.

- Food grade material – most plastic food contact products are made from polyethylene, and where at all possible metal is avoided

-

Posted: March 01, 2021Read more »

Hex Lok vs. Euro Thread

If you have ever had the experience of trying to connect the wrong threaded handle to a brush or squeegee head, you will know how different they are.

Or maybe you haven’t, so what is the difference?

Both thread types are suitable for the food industry and are resistant to unscrewing. Euro Thread is your typical thread type, featuring a tapered thread, and easily screws on and off. This a universal thread type and is typically quite endurable to circular motions. The Hex-Lok is a unique product with a hexagonal fitting, and an over fitting locking ring for maximum resistance.

The difference between them is the Hex-Lok solution can’t ‘unscrew’. When using deck scrubs and washing brushes, forming a pattern of ‘number 8’ is the most effective in ensuring maximum cleanliness, and how we naturally clean a surface. Often however, this loosens the end of the broom handle. While the Euro Thread has been

-

Posted: May 25, 2020Read more »

Resin set brushes are an advance on standard brushware. Resin-set increases bristle retention, and minimises the risk of harbouring bacteria in your brushware.

Resin set brushes are constructed in a similar manner to standard brushware, but an indented area is left around the bristle clumps.

The bristles are stapled into the brush block in the standard manner, then a liquid resin is poured around the bristle clumps. This seals off the bristle holes, and creates a smooth, flat finish around each bristle clump.

Using resin-set brushware gives additional peace of mind that your brushware won't be risking the integrity of your product.

-

Posted: January 20, 2020Read more »

Implementing a 5S system in your food processing facility may seem like a daunting task.

While there a many factors to be considered, and decisions to be made, making a start doesn’t need to be difficult.

Below is a simple checklist you can use to begin the process of implementing a 5S storage solution for your cleaning equipment.

It will give you an idea of what stage you are at, and what decisions will need to be made before beginning implementation.

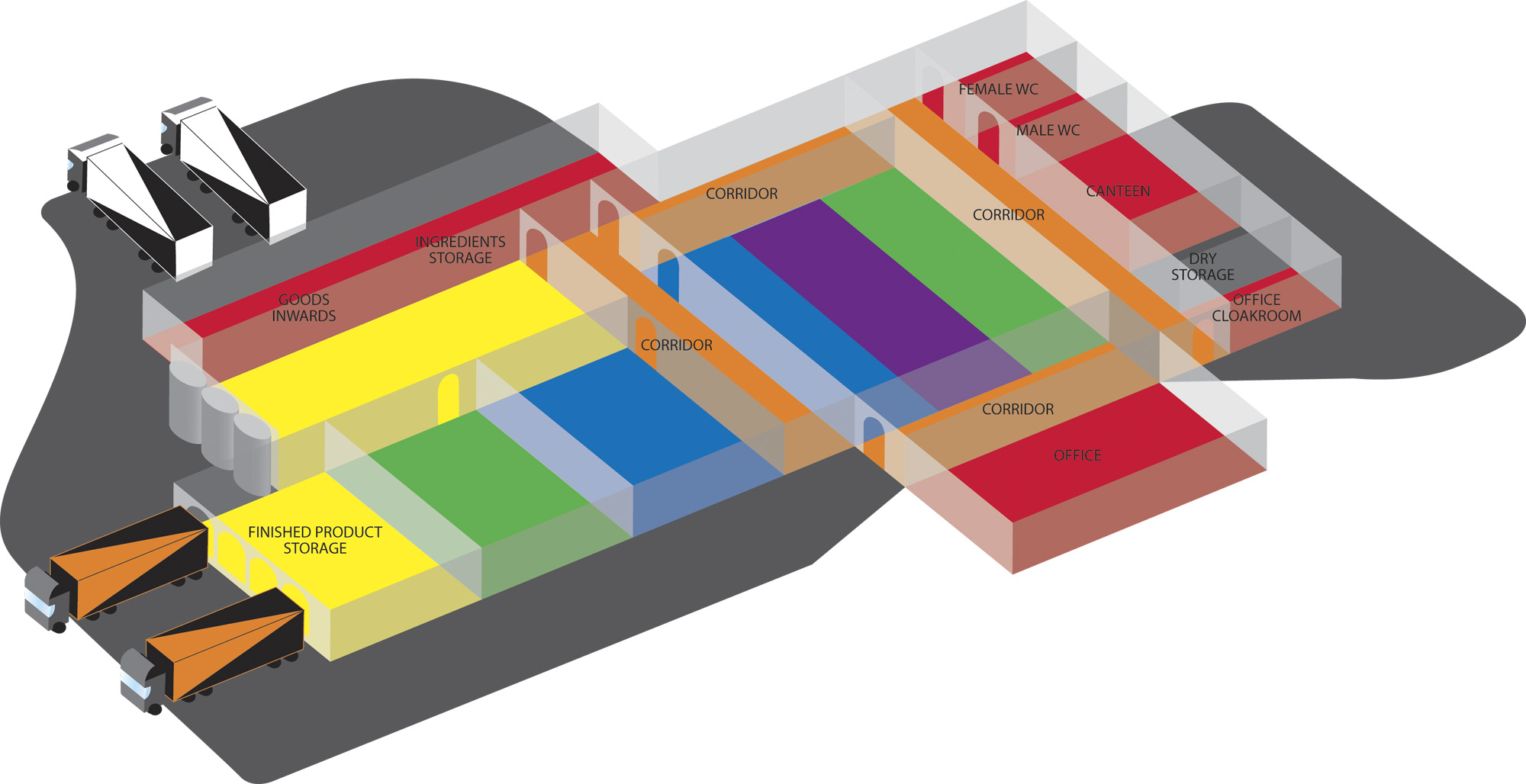

Do you currently have a colour code plan for your site (by area/allergen/process)?

Yes No Comments:Do you have a documented colour code plan that segregates different areas, products, or allergens? It is important to have this confirmed before going much further so that there aren’t changes later on to the colours you are using in each area.

Do

-

Posted: January 10, 2020Read more »

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility.

While not always a requirement, color-coding can demonstrate a company’s commitment to the quality and consistency of their products while maintaining a high level of safety for both their employees and consumers. It can be implemented to provide ‘zone control’ within a food processing or food service facility. Different colours can be assigned to each step in the process or by manufactory lines. When the colours are assigned to zones, confirming that a tool is misplaced is easy and tracing it back to its point of origination is quick.

1. Keep it simple - Limit the number of colours you use to keep it as simple as possible.

2. Pick contrasting colours - Red colour coded equipment is often associated and used with raw/uncooked meats. However, being aware of the potential problems

-

Posted: December 02, 2019Read more »

The Identi-Rail system is designed to make 5S implementation easy for food processors.

The modular system means:

-every station is entirely customised

-changes can be easily made to tool requirements

-a 5S system can be implemented then improved over time

Get in touch with one of the team to learn more about the range of 5S cleaning tool storage systems available.