What are the Benefits of Silverlined Gloves?

The food processing industry has valued silverlined gloves for many years. While Nitrile gloves have often replaced them, silverlined gloves are still preferred in many circumstances. There are a few points that make silverlined more suitable for various tasks.

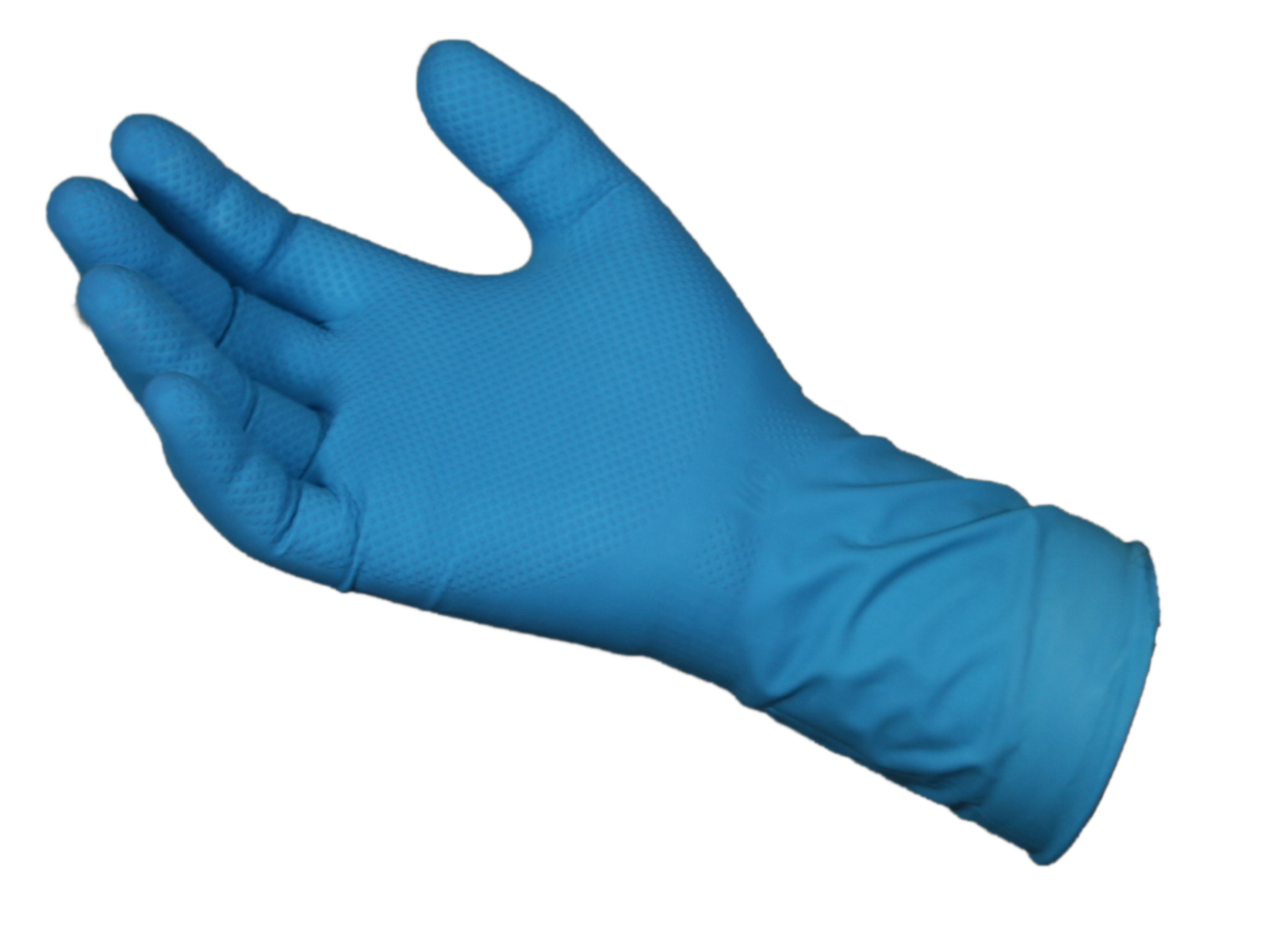

Let’s start with the term silverlined. This is an Australian term, which refers to the smooth ‘grey’ glove interior. This smooth texture is designed to make donning more efficient. The exterior of the glove (typically blue in the food industry) has a raised surface texture. Some common textures are honeycomb, fish-scale, pebble, sand patch or diamond. These are all excellent forms of grip to ensure ease of use... Sand patch is typically used in wet environments, while fish scale and diamond are more suitable for a dry environment, although these are interchangeable. Silverlined gloves are often referred to as ‘washing-up gloves’ as they are used in a domestic environment. They are the ideal heavy weight disposable glove.

One big topic around silverlined gloves is dexterity. As we know, ambidextrous is advantageous for the majority of disposable gloves. However, the thickness of the glove determines how stiff the glove is to use; indicating fine-motor skill tasks requiring a heavy-duty glove must be shaped to the natural curve of the hand. Having specific left-hand and right-hand glove is the obvious solution to accommodate for overall comfort and ergonomics.

The downside of having shaped gloves is the wastage. Typically packed in pairs, Silverlined gloves use more plastic packaging.

In situations where only one glove is required, such as using cut resistant gloves, means the other glove must be disposed. Previously, ambidextrous has been the only alternative to this wastage and the extra cost of gloves never used, and while appreciated by many for its cost-effective solution, it’s not suitable across all circumstances due to the glove being slightly thinner.

Silverlined gloves are still relevant in today’s food industry, and working together, we can help reduce the negative impact on the environment and still be able to improve food safety processes.

- Colour Coded Hygiene (17)

- Metal Detection (4)

- Food processing products (33)

- Product Comparisons (31)

- Food Safety (18)

- Procurement (11)

- 5S (5)