Food processing products

-

Posted: August 09, 2021Categories: Food processing productsRead more »

Wipes are used to make surfaces hygienic and clean. Their aim is to remove small particles, germs and or contaminates. They often partner up with chemicals for optimal results and are truly an essential part of cleaning. Used both during and between shifts, they are useful for removing accidental spills on the go, as well as in deep cleaning. Wipes come in many forms, and there is a number of factors to consider when choosing which wipe is the most appropriate for your needs.

Particularly important in the food processing industry are the colour options minimal lint. Using a blue option contrasts the cloth to the food, which is especially important in cloths and wipes as they are typically smaller and easy to misplace. Lint refers to the little bits of fluff, or when smaller particles of the wipe are left behind. Lint is considered a contamination risk, so choosing low lint options is especially important for critical production areas. Typically, the higher the quality of the

-

Posted: May 28, 2021Read more »

Dispensers in Food Production Facilities

Soap dispensers, paper towel dispensers, PPE dispensers: what makes a great design?

Efficiency is critical in production areas. Time, energy and effort are all limited, and need to be used carefully to ensure the maximum productivity.

Likewise, production consumables are just as essential in food manufacturing, for a range of purposes. The large volumes of these required demands efficient systems to allow for easy access and control so time isn’t lost and waste is controlled.

Over time, the ergonomics and basic functionality of dispensers have evolved making them more valuable and necessary in food processing than ever.

What is important in a dispenser?

A large amount of design goes into a highly functioning dispenser. Some of the basic considerations are hygiene control, reduced contact, limited waste and c

-

Posted: May 17, 2021Read more »

Bins, buckets and containers are designed for the transportation and storage of goods. They are commonly used in the food industry for the bulk storage for ingredients and other produce. The food industry’s high standard of hygiene requires specially designed products to minimize any risk, particularly for products that have contact with food. To ensure your storage methods are suitable and food safe, see below key features of bins, buckets and containers specifically designed for the food industry.

- Round edges – in the food industry all sharp edges are minimized to prevent mold and bacterial build up. These sharp angles are extremely difficult to clean sufficiently. It is vital to prevent all mold and contamination that may grow in grooves and edges, particularly in contact with food.

- Food grade material – most plastic food contact products are made from polyethylene, and where at all possible metal is avoid

-

Posted: May 03, 2021Read more »

Many types of gloves are available for Food manufacturing plants, including nitrile, vinyl and silverlined. A quality product that does not pose contamination risks to food production is paramount. Nitrile first became available in the 1990s and has become the most popular glove type within the food processing industry since then. There are many advantages to nitrile, and the varying thickness and options make it one of the most popular glove materials in the food processing industry.

Polyvinyl Chloride (PVC), or Vinyl gloves, as they are commonly referred to, are a relatively cheap option; they are a form of synthetic rubber and are stiff and less breathable than other materials. Their main benefit is their cost, usually considered reasonably cheap. Typically preferred when multiple ingredients are in use, gloves must be changed frequently.

However, due to their stiff nature, they often will tear when donning the glove, resulting in many employees choosing to wear two gloves

-

Posted: April 19, 2021Read more »

Reliable and competent hair control is essential for all food processing companies. Requirements can vary extensively by site, and each company must decide what is suitable for their needs, and what is required to meet their audit requirements. There are many kinds of hair control available and deciding on the right product must be chosen by a balance of quality, comfort, and suitability.

Falling under the hygiene wear sector, hair control products are typically disposable. A quality product features high strength breathable material, and tight enduring elastic while completely enclosing the hair. Hair control products are not effective unless they are worn unceasingly in the production area.

What variety of hair control is there?

The most common type is typically referred to as a hairnet. These are typically a crimped piece of non-woven polypropylene with an elastic edge. They typically cover the top of the head but will often fail to provide sufficient cover

-

Posted: February 15, 2021Read more »

What Makes a Product Hygienic?

One of the most important aspects of producing the food we all need and love, is maintaining good hygiene. Essentially, this involves keeping food processing areas clean with minimal risk of contamination. Keeping everyone from the producers to the consumers healthy and safe is of paramount importance.

There are many ways to ensure the safety of food by lowering potential risks. Different products, depending on their purposes, possess different features to ensure the minimum chance of contamination occurs.

Some of these main characteristics include:

Disposability

Many products that come in direct contact with food, are used only once and/or for a short period of time, such as one shift. This prevents cross contamination, particularly for industries that work with allergens. Also, single use products reduce the chance of harmful bacteria building up on gloves or clothing, that

-

Posted: June 25, 2020Read more »

There are two types of gumboots most commonly used in the food industry: PU (polyurethane) and PVC (poly-vinyl chloride).

Gumboots made from PVC are typically cheaper than PU, but they come with trade-offs.

Here are some of the main differences:

PVC gumboots are much heavier then PU. This means you are carrying up to 1kg of extra weight with every step you take, resulting in higher levels of fatigue.

PVC gumboots typically have a lifespan 1/3 the length of PU. This means gumboots need to replaced 3 times more often.

PVC gumboots also have a greater negative impact of the environment. PVC, typically known as vinyl, causes environmental damage both during manufacture and in landfill.

Due to their shorter lifespan, and greater weight, they also contribute to a much greater amount of landfill.

A typical food processing site with 200 staff wearing gumboots could

-

Posted: May 25, 2020Read more »

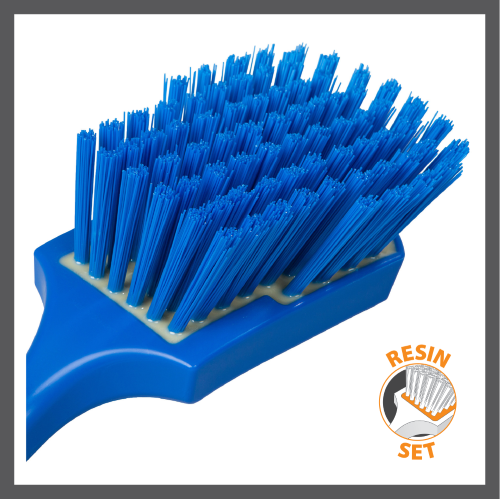

Resin set brushes are an advance on standard brushware. Resin-set increases bristle retention, and minimises the risk of harbouring bacteria in your brushware.

Resin set brushes are constructed in a similar manner to standard brushware, but an indented area is left around the bristle clumps.

The bristles are stapled into the brush block in the standard manner, then a liquid resin is poured around the bristle clumps. This seals off the bristle holes, and creates a smooth, flat finish around each bristle clump.

Using resin-set brushware gives additional peace of mind that your brushware won't be risking the integrity of your product.

-

Posted: January 17, 2020Read more »

There are a variety of different disposable gloves available, and knowing what option is best for your situation can be difficult.

Below is a brief overview of the 4 main types of disposable gloves.

Vinyl

Traditionally the most common type of glove, vinyl is now rarely used in food production facilities.

Their main advantage is their low cost per unit, although this can be deceptive if usage is higher through frequent breakages. Vinyl gloves are often preferred to wear, as they ‘breath’ and result in less sweaty hands. Obviously this is a serious contamination risk, and should be considered in your glove choice.

More recently, the environmental impact of the manufacture of vinyl has also come to light, which has further discouraged the use of vinyl gloves.

Nitrile

The most common glove type in food production facilities.

Nitrile gloves have a high strength, and a high dexterity. They are typ

-

Posted: December 09, 2019Read more »

Discussions with a range of food industry professionals in Australia has left little doubt; ATP testing has its place in a robust hygiene process, but it has its limitations, and it isn’t perfect – why?

Research by renowned biochemistry company Kikkoman Biochemifa has shed some interesting light on the process:

When you swab for ATP, you are only getting a third of the picture.

ATP testing is all based around a slightly flawed assumption- that ATP is a stable molecule that remains unchanged within organic residue.

In reality, ATP is easily hydrolysed to ADP and AMP by metabolic processes, heat treatment, or under acidic and alkaline conditions. Simply put, ATP (Adenosine Tri-Phosphate) will release a phosphoryl group to become ADP (Adenosine Di-Phosphate) and again to become AMP (Adenosine Mono-Phosphate).

The result: once food has been exposed to heat, water, acidic or alkaline properties, you may be testing for only a fraction of