Efficient waste management made easy

Could your waste be of value?

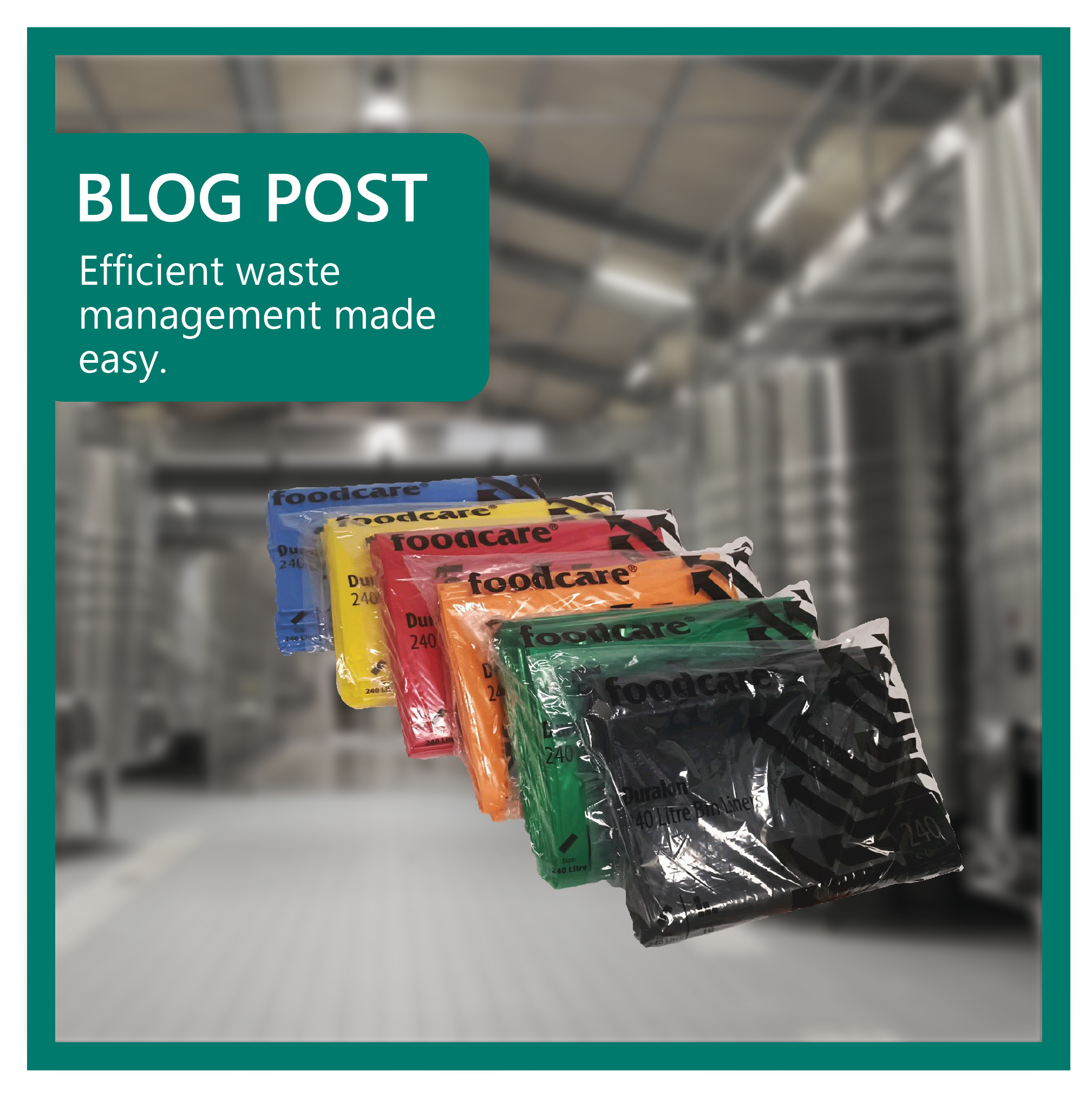

Efficiency and time are crucial factors for the success of any production site, to meet efficiency standards while reducing environmental impact. Although waste is an inevitable by-product of production, utilizing coloured bin liners allows for more efficient management and disposal of waste.

How can coloured bin liners help?

Colour coding has proven successful throughout the industry, as its quick visual recognition allows employees to speedily distinguish between ingredients. This prevents any potential health hazards such as cross-contamination. Coloured bin liners could be utilised in this same way. For example, to segregate ingredients that can be reused, recycled, composted, or that are potentially harmful.

All food production sites differ in what they produce and therefore the waste also varies. While you may not have many wasted ingredients, or you may have found ways to repurpose these ingredients, bin liners can help by sorting these efficiently and allowing employees to know what to do with the contents of that specific colour.

Various coloured bin liners can be used to sort and segregate in a food manufacturing environment. Some (only) examples:

- Red could be used for waste by-products of processing.

- Orange for allergenic waste.

- Blue for re-work products

- Black for hazardous/toxic waste

- Green for recyclable packaging materials

An alternative to this could be red for outside the facility, blue for production areas, and yellow for the warehouse. It’s all your choice.

We understand saving time and money is paramount to production sites. If coloured bin liners would be of use to you, click through to our bin liner page to request a sample.