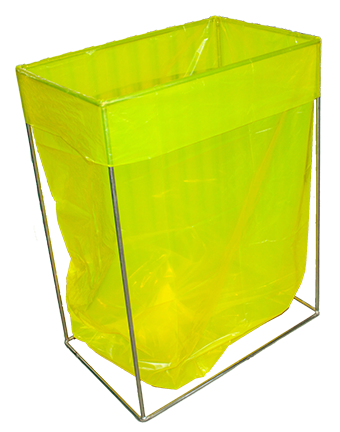

Efficient waste management is key to reducing costs and improving productivity, but it’s not always straightforward. Colour-coded bin liners offer a simple yet effective solution by visually separating waste for better analysis and reduction strategies—whether through training, process updates, or material changes.

Our industry-first Duralon60 colour-coded bin liners make waste segregation easier and more efficient. Designed for food production, these heavy-duty, food-contact-approved liners come in six colours to help:

Reduce time spent on waste sorting

Improve contamination control

Increase recycling opportunities

Available in 82L and 240L, Duralon60 bin liners are a small change that can make a big impact—because in food processing, every improvement counts.

How they can be utilized:

- Segregate areas/lines to locate where high volumes are.

- Segregate types of waste, such as recycling, food scraps, etc.

- Segregate consumables - for instance, gloves from other waste to analyse breakage more thoroughly.

- Segregate between shifts - which is the most economical?

- Segregate between liner changes to know how long the rubbish has been exposed - reduce bacteria spreading.

- Complement your colour coding system.

- Cost savings from reducing waste.

Efficiency and time are crucial factors for the success of any production site, to meet efficiency standards while reducing environmental impact.

Read more

Related Products