Food Safety

-

Posted: October 15, 2021Read more »

While large parts of the Australian food processing market are now automated, there are still inevitably areas where contact with food is necessary. While we typically think of this in terms of gloves, there are many other materials that also come into contact with food. How and why are some products appropriate and others not?

Hygiene and quality are two of the highest priorities. So, it is critical to assess what materials come into contact with food at all times.

Some of the more familiar materials include plastic, metal, rubber, and textiles. Some materials such as glass ae now rarely found in food production areas. Glass is often considered too dangerous to be allowed into production areas, its brittleness increases the potential of it smashing and contaminating food with sharp shards. This is obviously unacceptable, and many food facilities are glass free.

Textiles, such as cotton gloves, hair nets and wipes, are generally suitable and food

-

Posted: September 17, 2021Read more »

Coveralls are considered an essential piece of protective wear in most food production areas. As their name suggests, a coverall is a single garment that covers the entire body, trousers, top and hood. The purpose of a coverall is to protect the worker’s body and clothes from messy or hazardous labor-intensive jobs.

Some coverall features that many customers find important include elastic cuffs, hoods, sealable zip cover, water resistant and breathable material, colour variance and a range of sizes.

- Both disposable and reusable coveralls are used throughout the industry. While they share many features, the disposable options are often preferred as they can be replaced easily, and not likely to harbor bacteria.

- Hoods and elastic cuffs both serve a similar purpose, protecting the worker by preventing irritating materials making contact with skin.

- Water resistance or protection levels are usually described by European Standards called

-

Posted: July 12, 2021Categories: Food SafetyRead more »

Food recalls are an outcome food manufactures avoid at all costs. They occur when food is considered unfit for consumption or is a serious health risk to the community. They are expensive and have damaging consequence to the manufacture. Awareness of food safety has increased extensively, and there are now many systems and products to manage and ensure food safety.

Food recalls are issued by governments on a state or territorial level and are managed by FSANZ (Food Safety Australia and New Zealand). FSANZ are responsible for ensuring awareness, and that products are removed from shelves.

A few of the common causes of food recalls include:

- Foreign matters -this includes anything that has or may have fallen into the food, causing a contamination risk.

- Allergens - if a product has an undeclared allergen in it, or not clearly labeled the public must be notified.

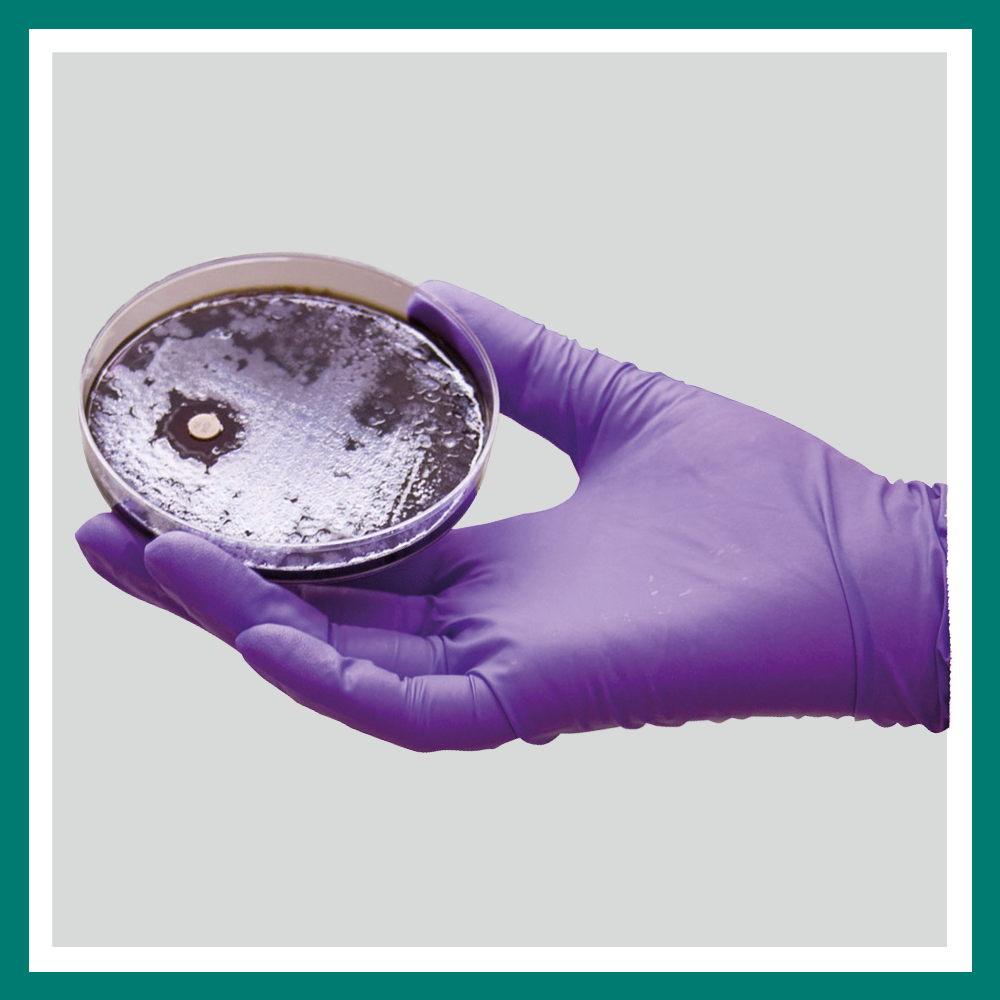

- Biotoxin/ microbial – containing

-

Posted: June 15, 2021Categories: Food SafetyRead more »

Food is essential, and something we all thrive on; we require good food for our health and as an enjoyable feature of our social lives. But how can something we both enjoy and require, harm us?

There are many types of illnesses caused or linked to food. Some of the most common include Salmonella, E.coli, Clostridium perfringens, Hepatitis, Campylobacter Staphylococcus aureus (aka staph) Norovirus and Listeria. Food illnesses can occur in domestic situations, however, with more people preferring the convenience of bought meals and snacks, it is important that we help reduce the risk of food poisoning, by minimising any potential contamination.

How do food illnesses start? Bacteria, virus, and parasites are all around us in our day to day lives, which is why we have immune systems. However, they become harmful to humans when they multiply or spread, if we are not immune to them, or consume too much. When food becomes affected by a foreign bacteria/virus it is considered

-

Posted: February 15, 2021Read more »

What Makes a Product Hygienic?

One of the most important aspects of producing the food we all need and love, is maintaining good hygiene. Essentially, this involves keeping food processing areas clean with minimal risk of contamination. Keeping everyone from the producers to the consumers healthy and safe is of paramount importance.

There are many ways to ensure the safety of food by lowering potential risks. Different products, depending on their purposes, possess different features to ensure the minimum chance of contamination occurs.

Some of these main characteristics include:

Disposability

Many products that come in direct contact with food, are used only once and/or for a short period of time, such as one shift. This prevents cross contamination, particularly for industries that work with allergens. Also, single use products reduce the chance of harmful bacteria building up on gloves or clothing, that

-

Posted: February 01, 2021Categories: Food SafetyRead more »

What is HACCP?

HACCP is a standard that helps to ensure the safety of food around the world. It stands for Hazard Analysis and Critical Control Points.

As the name suggests, HACCP identifies and removes potential risks and hazards in the food industry. This eliminates risks to the end consumer, while guaranteeing the quality of the products they purchase.

As there are many different regulations according to countries and regions, it is essential to find the relevant information for your company.

How does HACCP work?

For a business to be HACCP approved they must undertake an audit, where the production lines and systems are assessed in their safety in relation to food.

Anything that has contact with food is thoroughly examined and carefully analysed for potential risks, such as the chance of contamination, and the likelihood of occurrence.

From there, measures

-

Posted: March 10, 2020Categories: Food SafetyRead more »

You may have always thought these two terms meant the same thing. Or maybe you know they’re different but not sure what each one means.

So, what does each one actually mean?

In short, food grade means that the material is suitable to come into direct contact with food.

And food safe means that the food grade material and finished product is suitable for it’s intended use and will not create a food safety hazard.

The key difference here is regarding materials, and finished products.

Food grade typically refers to a material, and essentially states that the material doesn’t contain any toxins or dangerous substances. For something to be considered food grade, the material must be able to be cleaned effectively, and not allow any foreign particles to find their way into food. Generally, the surface should be smooth and free of any imperfections such as cracks, ridges or crevices, where bacteria could grow.

When this material is used to create

-

Posted: December 09, 2019Read more »

Discussions with a range of food industry professionals in Australia has left little doubt; ATP testing has its place in a robust hygiene process, but it has its limitations, and it isn’t perfect – why?

Research by renowned biochemistry company Kikkoman Biochemifa has shed some interesting light on the process:

When you swab for ATP, you are only getting a third of the picture.

ATP testing is all based around a slightly flawed assumption- that ATP is a stable molecule that remains unchanged within organic residue.

In reality, ATP is easily hydrolysed to ADP and AMP by metabolic processes, heat treatment, or under acidic and alkaline conditions. Simply put, ATP (Adenosine Tri-Phosphate) will release a phosphoryl group to become ADP (Adenosine Di-Phosphate) and again to become AMP (Adenosine Mono-Phosphate).

The result: once food has been exposed to heat, water, acidic or alkaline properties, you may be testing for only a fraction