The Extendabag system is ideal for the food industry. Hygienic, robust, labour saving, efficient, and practical. It works by simply loading the cassette onto the bin and sealing the bottom off with a cable tie.

The extra strong cassettes are three ply, making it one of the strongest bin liner materials available. This paired with the system - allows the bin to be filled until it suits you to replace it, such as the end of the shift - instead of replacing mid shift. This not only efficient - but eliminates the need for constant supervision.

Ergonomic? Absolutely - with the bin liner only being replaced when it suits, this can result in a heavy load. lifting a full liner out of a standard bin, can cause back strain. The Extenda bag system, however, allows the liner to pulled out from underneath - reducing the need to lift it above waist height.

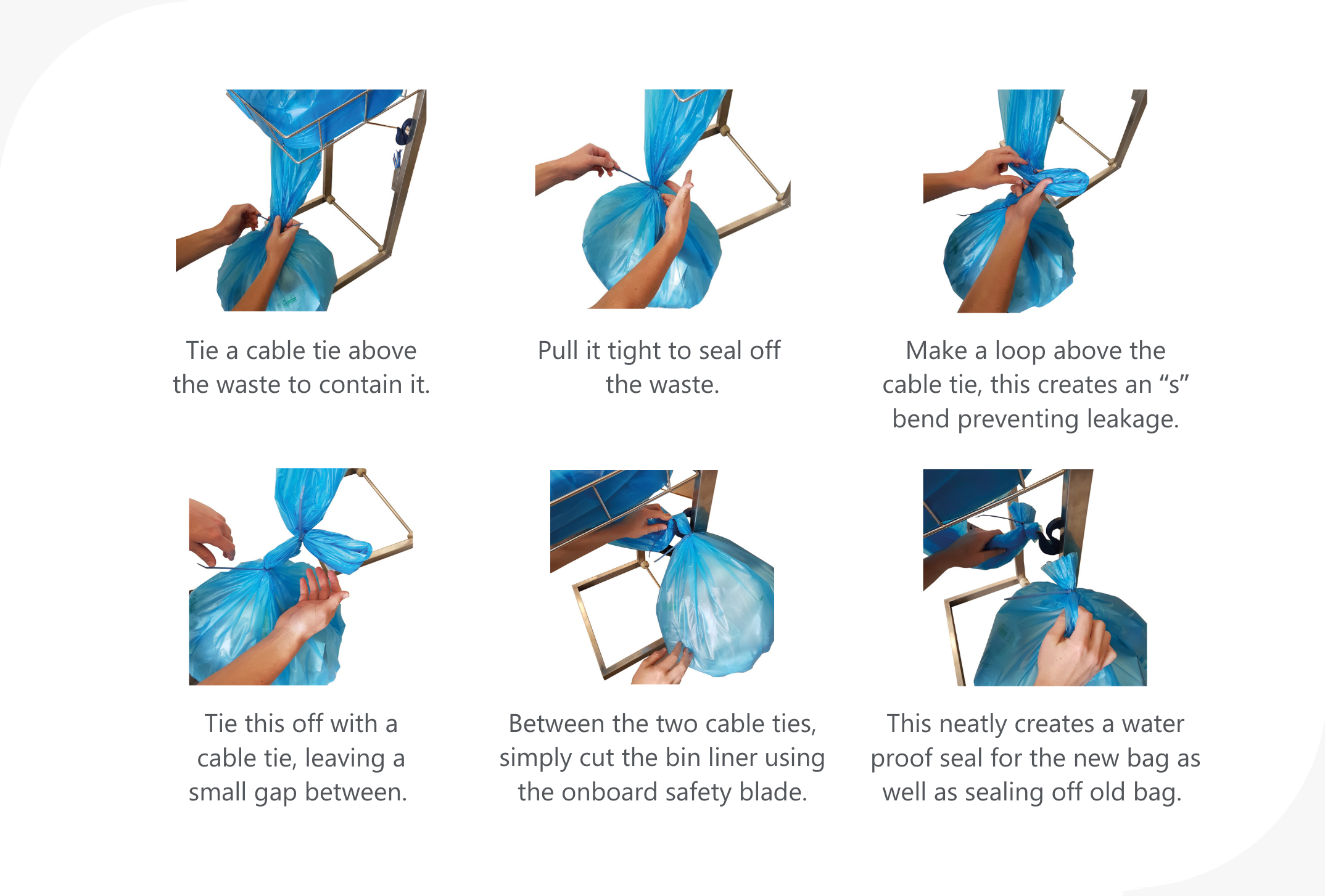

The bin stand has wheels, ensuring mobility within your production area, it comes with an onboard safety blade, and a storage compartment for the cable ties. It's strong robust stainless-steel structure, makes it an investment for your site.

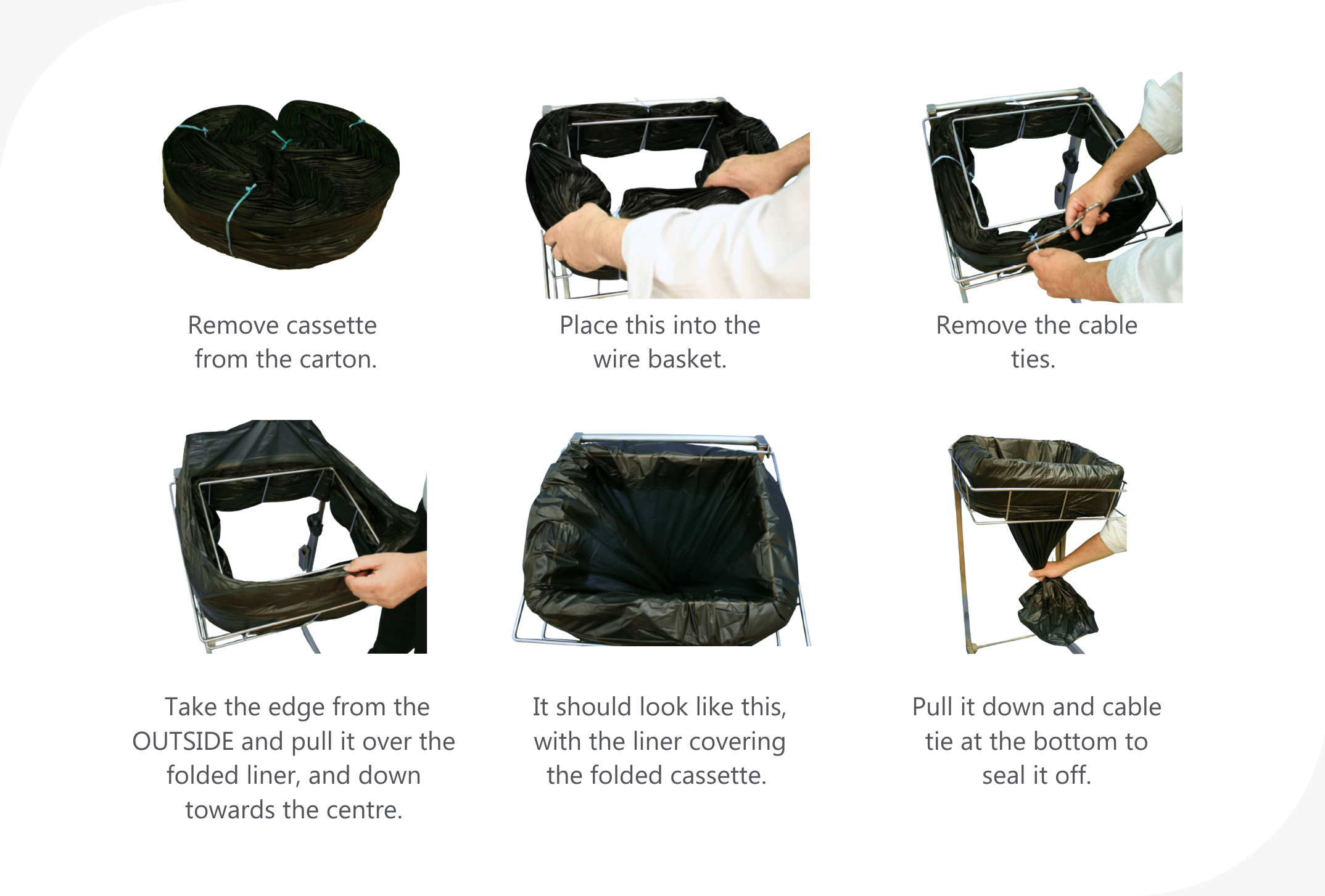

Designed to also be hygienic, the waste is drawn inside, ensuring no contact with the operator, and reducing the likely hood of cross contamination. However, it is important to load the cassette correctly, visuals below demonstrate this for you.

Interested in the Extenda bag system?

Contact our team for pricing.

How to apply the cassette

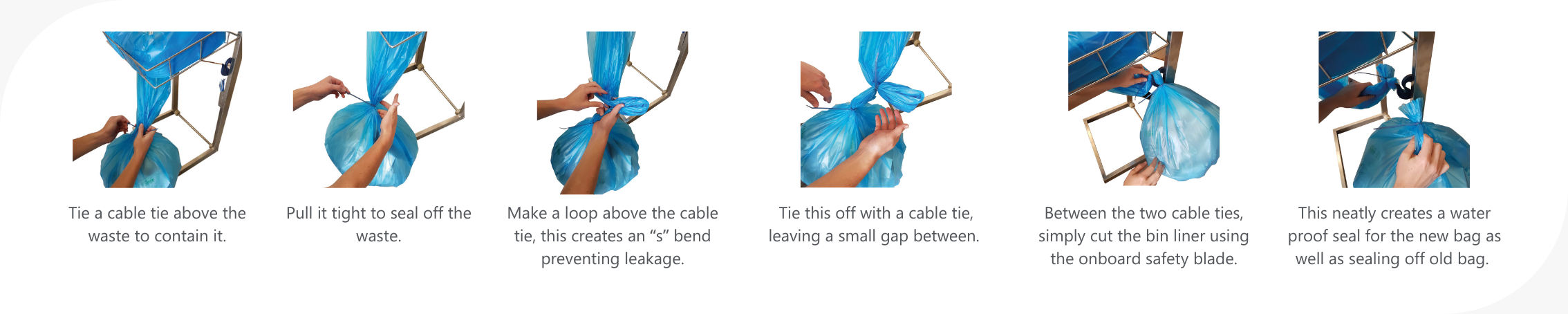

How to create a liquid proof bin liner

Click through to visit our product pages