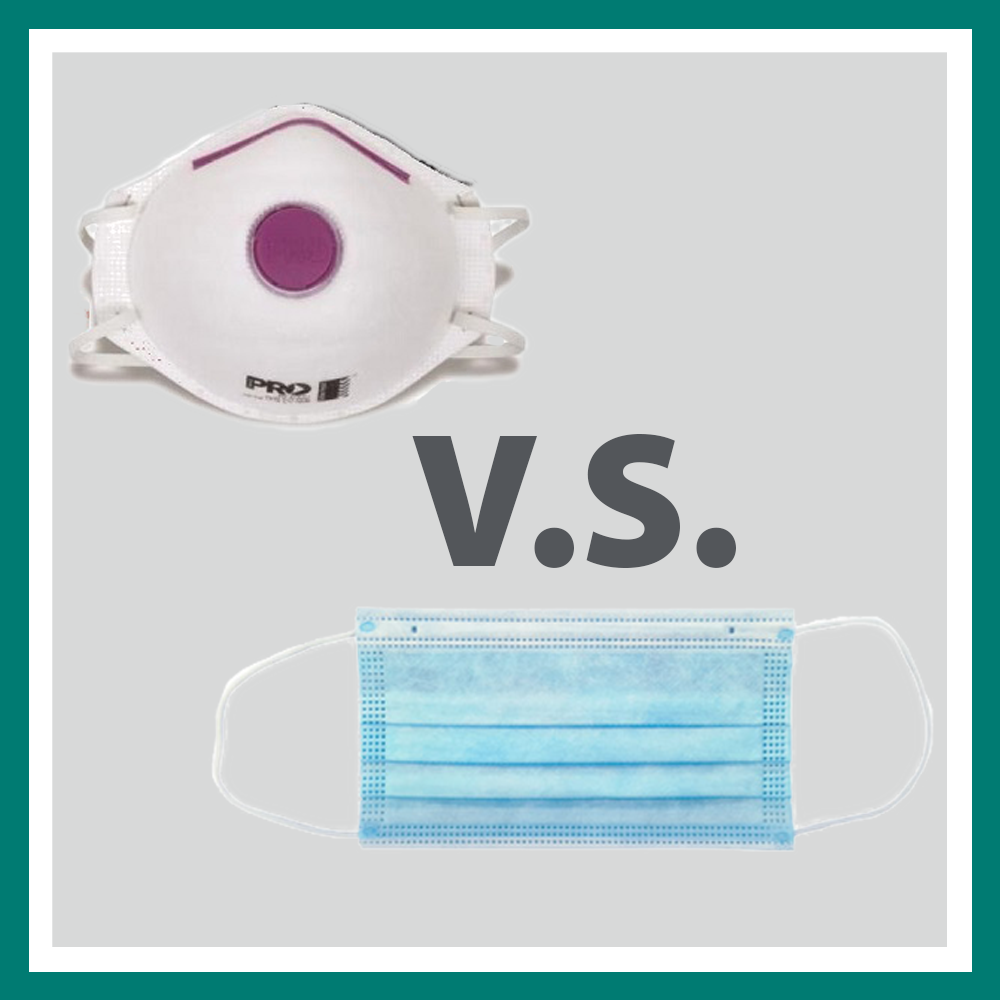

Mask vs Respirator in Food Manufacturing

In these unprecedented times masks have become very familiar to us, but what is the difference between a mask and a respirator in their application in food manufacturing?

In our industry, masks are generally worn to protect food from the wearers respiratory emissions and a respirator is generally worn to reduce the wearers exposure to harmful particles that may be present in the air.

In many environments within the food processing industry, air quality is affected by the tasks performed, for instance, anything involving fine powders, chemicals, or dust. Our lungs are able to withstand a small amount of exposure and naturally filter out harmful particles, however being repeatedly or regularly exposed can create a build-up with potential long-term damage. Confined spaces also pose a risk as fumes and or powders are unable to disperse. So, protecting our respiratory system is important, and ensuring we aren’t spreading germs is also critical, particularly while working with food. So how do we determine which product we need?

Respirators:

Respirators are designed to protect the respiratory system. They are usually cup shaped sitting closely on the face, held firmly with one or two pieces of elastic, covering both the nose and mouth. There are many different types of respirators, obviously depending on what is affecting the air quality such as cleaning chemicals or flour will determine the type you require. Some respirators have valves which improves the wearer comfort, as it increases air flow. Which type or level of respirator you will need will generally be determined by your Quality Assurance professional or other qualified members of your team.

Masks:

Masks also filter what we breathe, although to a lesser extent than a respirator, they are used as a precautionary measure. Mask standards and ratings, as with respirators, vary by country so it’s worthwhile looking at a mask comparison chart to get a full understanding of the effectiveness of your mask, or respirator, to ensure Australian compliance.

Masks and respirators are easily contaminated during use when touched or adjusted by the wearers hands so it’s good to ensure staff wear masks that have a good and comfortable fit when they are used for long periods of time on the production floor. Good hand hygiene when applying and removing a mask or respirator cannot be underestimated.

This blog post does not cover covid precautions that may be necessary for your business.