Food Related Illnesses and how to Prevent Them

Food is essential, and something we all thrive on; we require good food for our health and as an enjoyable feature of our social lives. But how can something we both enjoy and require, harm us?

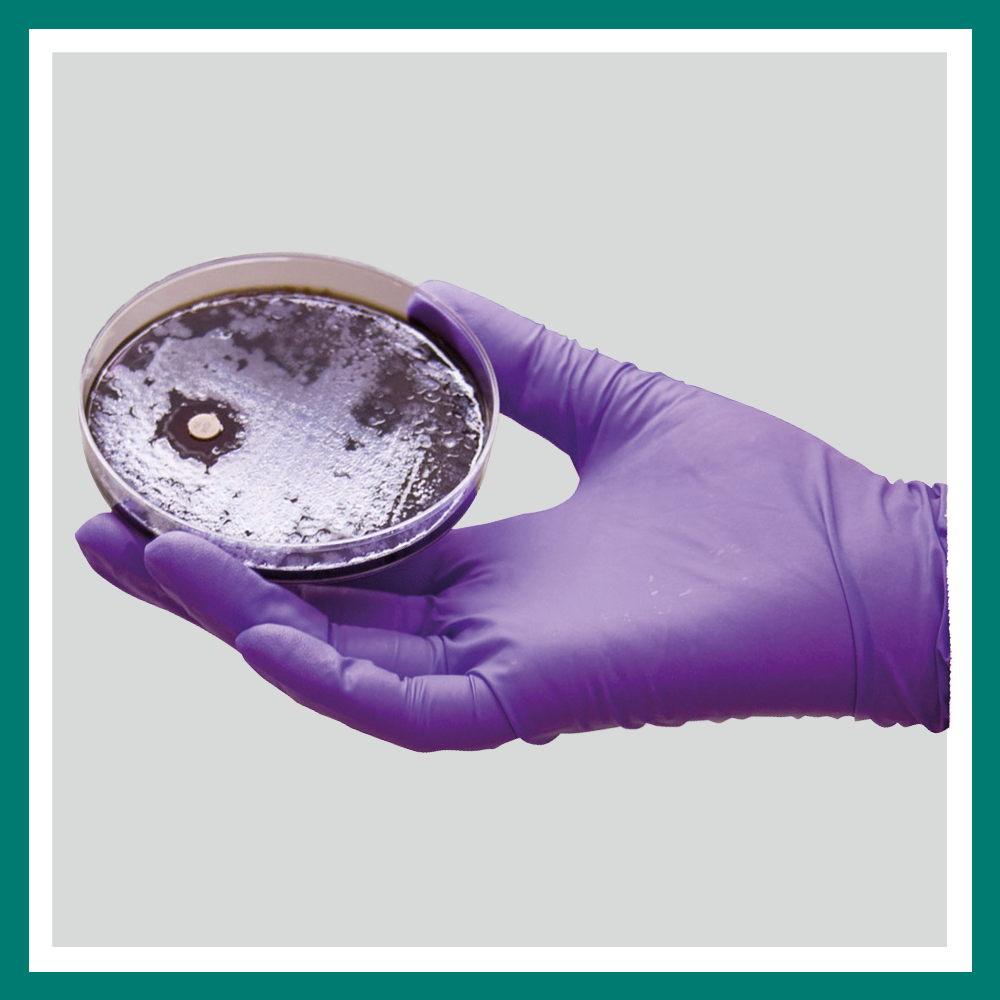

There are many types of illnesses caused or linked to food. Some of the most common include Salmonella, E.coli, Clostridium perfringens, Hepatitis, Campylobacter Staphylococcus aureus (aka staph) Norovirus and Listeria. Food illnesses can occur in domestic situations, however, with more people preferring the convenience of bought meals and snacks, it is important that we help reduce the risk of food poisoning, by minimising any potential contamination.

How do food illnesses start? Bacteria, virus, and parasites are all around us in our day to day lives, which is why we have immune systems. However, they become harmful to humans when they multiply or spread, if we are not immune to them, or consume too much. When food becomes affected by a foreign bacteria/virus it is considered contaminated. Contamination typically occurs from one of the following.

- Food is cooked or stored at incorrect temperatures; the danger zone is between 5-60`C

- Cleaning is insufficient, either of the environment, personnel, or utensils

- Cross-contamination has occurred, (particularly of raw ingredients or allergens)

- The ingredients have come from an unreliable source or been exposed to germs before arriving.

The majority of food companies are advanced in food safety, and it is an issue closely monitored by audits and other food authorities. However, awareness of advancements in the industry may benefit your company both in the short and long term.

Some available options to monitor and control food safety are:

- Cleaning: cleaning is a big subject and imperative for food safety. The two main considerations are thoroughness and regularity. This of course is dependent on the type of food and process. There is a large variety of cleaning methods from wiping, brushing, and high-pressure hosing. Which is used is dependent on the company and their production line. Some modern ways to test cleanliness include ATP testing and Total Plate Counts.

- Cleaning utilities: there are many types of brushes, squeegees, mops, and brooms designed for the food industry. Each are suited to different purposes, from fine powders to hard substances. It is important to ensure your equipment is food grade. Another excellent practice is colour coding, specifically used for allergens, but also recommended for high-risk foods.

- Temperature: Heat kills bacteria, this prevents it from growing and spreading. Constantly monitoring temperatures is vital, which can be achieved with a variety of thermometers and data loggers.

- Hygiene: the hygiene of employees is critical, as bacteria and viruses can be transmitted from human to food. While it is hard to detect this transmission of disease, the risk can be prevented with the correct disposable wear. Hygiene-wear is a big subject, and again is dependent on the industry, though gloves are always recommended.

Food illness is suffered by 4.1 million Australians annually. This highlights the criticalness of food safety, and the need to ensure best practices are in place for the good and safety of the community.

Information sourced from: https://www.foodauthority.nsw.gov.au/consumer/food-poisoning